Help me with the joining of the drawers-Miller Dowel System?

both

13 years ago

Related Stories

HOUSEKEEPINGThree More Magic Words to Help the Housekeeping Get Done

As a follow-up to "How about now?" these three words can help you check more chores off your list

Full Story

SMALL SPACESDownsizing Help: Storage Solutions for Small Spaces

Look under, over and inside to find places for everything you need to keep

Full Story

HOUZZ TOURSMy Houzz: 38 Years of Renovations Help Artists Live Their Dream

Twin art studios. Space for every book and model ship. After four decades of remodeling, this farmhouse has two happy homeowners

Full Story

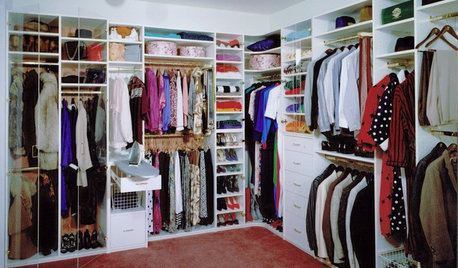

ORGANIZINGGet the Organizing Help You Need (Finally!)

Imagine having your closet whipped into shape by someone else. That’s the power of working with a pro

Full Story

Storage Help for Small Bedrooms: Beautiful Built-ins

Squeezed for space? Consider built-in cabinets, shelves and niches that hold all you need and look great too

Full Story

MOST POPULAR7 Ways to Design Your Kitchen to Help You Lose Weight

In his new book, Slim by Design, eating-behavior expert Brian Wansink shows us how to get our kitchens working better

Full Story

DECLUTTERINGDownsizing Help: How to Edit Your Belongings

Learn what to take and what to toss if you're moving to a smaller home

Full Story

LIFEYou Said It: ‘Put It Back’ If It Won’t Help Your House, and More Wisdom

Highlights from the week include stopping clutter from getting past the door, fall planting ideas and a grandfather’s gift of love

Full Story

KITCHEN DESIGNIdea of the Week: Customizable Dish Drawer

Tuck dishes safely away in a DIY kitchen-drawer organizer

Full Story

MOST POPULAR8 Ways to Get a Handle on the Junk Drawer

Don’t sweat the small stuff — give it a few drawers of its own, sorted by type or task

Full Story

Jon1270

bothOriginal Author

Related Professionals

South Riding Cabinets & Cabinetry · Watauga Cabinets & Cabinetry · Golden Glades Carpenters · Chesapeake Flooring Contractors · Fairfax Flooring Contractors · Fort Lauderdale Flooring Contractors · Golden Glades Flooring Contractors · Pearland Flooring Contractors · Stoughton Flooring Contractors · Thornton Flooring Contractors · Woodbury Flooring Contractors · Denver Furniture & Accessories · Roseville Furniture & Accessories · Highland Park Furniture & Accessories · Mahwah Furniture & AccessoriesUser

someone2010

someone2010

Jon1270

brickeyee

aidan_m

brickeyee