routing of sink cut out

PoorOwner

15 years ago

Featured Answer

Sort by:Oldest

Comments (13)

aidan_m

15 years agoRelated Professionals

Key Biscayne Cabinets & Cabinetry · Riverbank Cabinets & Cabinetry · Boca Raton Flooring Contractors · Faribault Flooring Contractors · Hastings Flooring Contractors · Oregon City Flooring Contractors · Orem Flooring Contractors · Redlands Flooring Contractors · Slidell Flooring Contractors · West Chester Flooring Contractors · Whitman Flooring Contractors · Boston Furniture & Accessories · Charleston Furniture & Accessories · Beverly Hills Furniture & Accessories · Urbandale Furniture & Accessoriesjustnigel

15 years agoPoorOwner

15 years agoMongoCT

15 years agoJon1270

15 years agoMongoCT

15 years agoJon1270

15 years agoPoorOwner

15 years agobrickeyee

15 years agoMongoCT

15 years agoPoorOwner

15 years agoMongoCT

15 years ago

Related Stories

LANDSCAPE DESIGNTake Your Garden on a Rural Route With Plant-Dominant Designs

Let plants take center stage for a garden that recalls idyllic pastures fashioned by nature's hand

Full Story

KITCHEN DESIGNKitchen Counters: Try an Integrated Cutting Board for Easy Food Prep

Keep knife marks in their place and make dicing and slicing more convenient with an integrated butcher block or cutting board

Full Story

DECORATING GUIDESSpring Style: Fresh-Cut Flowers for Every Room

Graceful, lively or dramatic, fresh flowers make rooms of every shape, size and style that much lovelier

Full Story

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

KITCHEN DESIGNButcher Block Makes the Cut for Holiday Kitchen Prep

Countertops and cutting boards will likely take a beating over the holidays. These butcher blocks have the chops to perform under pressure

Full Story

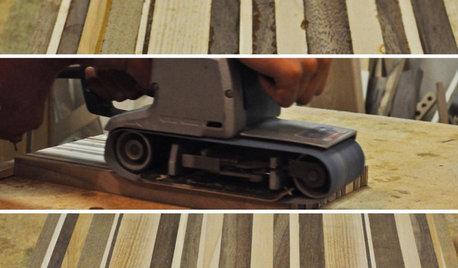

DIY PROJECTSFashion a High-Quality Cutting Board From Scrap Wood

Waste not, want not. This DIY project saves scraps from the landfill, hones your woodworking skills and produces a gorgeous kitchen piece

Full Story

BUDGET DECORATINGSimple Pleasures: Treat Yourself to Cut Flowers

Enjoy priceless beauty with just a few inexpensive stems — and you don’t need fancy vases, either

Full Story

KITCHEN DESIGNBreaking Out of the Kitchen Work Triangle

Keep the efficiency but lose the rigidity with kitchen designs that don't box you in

Full Story

KITCHEN DESIGNClever Extras for a Perfectly Personalized Kitchen Sink

Streamline cooking prep and cleanup with integrated sink racks, baskets, inventive cutting boards and more

Full Story

KITCHEN DESIGNTrick Out Your Kitchen Backsplash for Storage and More

Free up countertop space and keep often-used items handy by making your backsplash more resourceful

Full StorySponsored

Columbus Area's Luxury Design Build Firm | 17x Best of Houzz Winner!

More Discussions

Jon1270