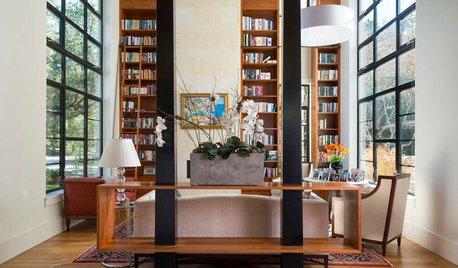

Shelf Structure

Vertise

11 years ago

Related Stories

TASTEMAKERSImm Cologne Show Stunners: 9 Artful Shelf and Storage Designs

Organizing is a joy with these latest offerings in bookcases and storage systems from the imm Cologne show

Full Story

DECORATING GUIDES9 Tips for Making Your Shelf Display Look Great

Learn the tricks stylists use when arranging objects on a shelf

Full Story

MOST POPULARHow to Add a Backyard Shed for Storage or Living

Need a home office, a playspace or extra room for your stuff? Learn about off-the-shelf, prefab and custom sheds

Full Story

HOUZZ TVHouzz TV: Cool Reclaimed Wood Projects Fill a Craftsman’s Home

Using barn wood, beadboard and beams, this homeowner has crafted furnishings and features for his family’s Chicago home

Full Story

REMODELING GUIDESGreat Ways to Dress Up Those Necessary Columns

Many homes need a structural column or two, especially in today's open-plan spaces. Here's how to turn them into superstars

Full Story

CURB APPEALKnow Your House: Anatomy of a Brick Veneer Wall

Brick's new role as skin versus structure offers plenty of style options for traditional exteriors

Full Story

WORKING WITH PROSWhat to Know About Working With a Custom Cabinetmaker

Learn the benefits of going custom, along with possible projects, cabinetmakers’ pricing structures and more

Full Story

HOUZZ TOURSHouzz Tour: Visit a Forward Thinking Family Complex

Four planned structures on a double lot smartly make room for the whole family or future renters

Full Story

TRADITIONAL STYLETraditional Accents: Corbels for Flourish and Fun

These once-simple structural details now stand on their own as home décor

Full Story

ARCHITECTURE21 Creative Ways With Load-Bearing Columns

Turn that structural necessity into a design asset by adding storage, creating zones and much more

Full StoryMore Discussions

talley_sue_nyc

VertiseOriginal Author

Related Professionals

Wildomar Cabinets & Cabinetry · Short Hills Cabinets & Cabinetry · Champaign Carpenters · Parsippany Carpenters · Tonawanda Carpenters · Cartersville Flooring Contractors · Louisville Flooring Contractors · North Hollywood Flooring Contractors · Snellville Flooring Contractors · Englewood Flooring Contractors · Charleston Furniture & Accessories · Silver Spring Furniture & Accessories · Westport Furniture & Accessories · Springdale Handyman · Fish Hawk Handymanmary_ruth

brickeyee

VertiseOriginal Author

brickeyee

VertiseOriginal Author

lazy_gardens

VertiseOriginal Author

talley_sue_nyc

VertiseOriginal Author

brickeyee

VertiseOriginal Author

talley_sue_nyc

VertiseOriginal Author

brickeyee

VertiseOriginal Author

lazy_gardens

VertiseOriginal Author

brickeyee