tree trunk slice table top

danfurmanek

16 years ago

Featured Answer

Comments (18)

Jon1270

16 years agoRelated Professionals

Bedford Carpenters · Dallas Carpenters · Leander Carpenters · Ridgewood Carpenters · Dunwoody Flooring Contractors · Limerick Flooring Contractors · New Orleans Flooring Contractors · Orange Flooring Contractors · Westlake Flooring Contractors · Lorton Furniture & Accessories · Minneapolis Furniture & Accessories · Nashville Furniture & Accessories · Ventura Furniture & Accessories · Lake Arrowhead Furniture & Accessories · Sugar Hill Furniture & Accessoriesbhrost

16 years agoJon1270

16 years agobrickeyee

16 years agoleslieegerton_hotmail_com

16 years agorobynpa

16 years agohenrys

15 years agohuffg311_hotmail_com

13 years agoJon1270

13 years agobrickeyee

13 years agoarter626_hotmail_com

13 years agoJon1270

13 years agopoppadiamond

12 years agobrickeyee

12 years agodarstar7561

12 years agofmanheim

11 years agobrickeyee

11 years ago

Related Stories

DECORATING GUIDESBring Nature Indoors With Tree Stumps, Trunks and Logs

Furniture formed from wood in its natural state adds earthy elegance to any room

Full Story

FURNITUREGnarly End Tables!

Tree Trunks and Stumps Bring Freeform Warmth to All Kinds of Spaces

Full Story

TREESHow to Use Trees Inside

Bring nature close by integrating the beauty of trunks and trees — even smaller leafy trees — into your home

Full Story

GARDENING GUIDESHow to Keep Your Citrus Trees Well Fed and Healthy

Ripe for some citrus fertilizer know-how? This mini guide will help your lemon, orange and grapefruit trees flourish

Full Story

CRAFTS7 Ways to Upcycle a Fallen Tree

When a tree falls, turn its branches into rustic toys, accessories and holiday décor

Full Story

FURNITURE8 Ways to Reimagine the Coffee Table

A Trunk, Ottoman, Cart and More Can Become the Center of the Living Room

Full Story

THE ART OF ARCHITECTUREOutside In: You, Me and Nature, Cozy Together

From reclaimed tree trunks to soaring coastal views, designers and homeowners are finding ways to bring the inspiring outdoors inside

Full Story

DECORATING GUIDESPalm Trees Take Interiors on a Tropical Vacation

Conjure a sultry vibe or bring welcome life to modern rooms. Whatever your interior design style, palm trees are the ticket to enhancing it

Full Story

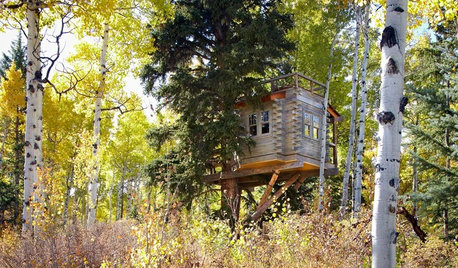

TREE HOUSESSwaying From Sleepovers to Dinner Parties in a Colorado Tree House

Folks of all ages have it made in the shade in this fun little house, thanks to electricity, a kitchenette and a rooftop deck

Full StoryMore Discussions

danfurmanekOriginal Author