3 Inch Thick Rough Cut Oak Slabs

glimm

16 years ago

Related Stories

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

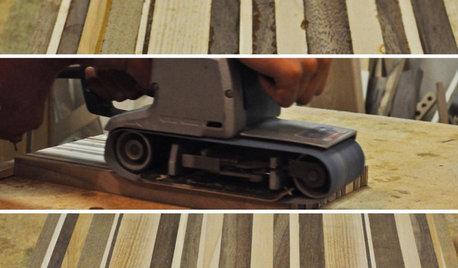

DIY PROJECTSFashion a High-Quality Cutting Board From Scrap Wood

Waste not, want not. This DIY project saves scraps from the landfill, hones your woodworking skills and produces a gorgeous kitchen piece

Full Story

KITCHEN DESIGN3 Steps to Choosing Kitchen Finishes Wisely

Lost your way in the field of options for countertop and cabinet finishes? This advice will put your kitchen renovation back on track

Full Story

KITCHEN DESIGNKitchen Remodel Costs: 3 Budgets, 3 Kitchens

What you can expect from a kitchen remodel with a budget from $20,000 to $100,000

Full Story

KITCHEN COUNTERTOPSKitchen Counters: Granite, Still a Go-to Surface Choice

Every slab of this natural stone is one of a kind — but there are things to watch for while you're admiring its unique beauty

Full Story

REMODELING GUIDESYour Floor: An Introduction to Solid-Plank Wood Floors

Get the Pros and Cons of Oak, Ash, Pine, Maple and Solid Bamboo

Full Story

BATHROOM DESIGNWater Damage Spawns a Space-Saving Bathroom Remodel

A game of inches saved this small New York City bathroom from becoming too cramped and limited

Full Story

KITCHEN CABINETSNew This Week: 3 Modern Kitchens That Rock Warm Wood Cabinets

Looking for an alternative to bright white? Walnut cabinetry offers the perfect tone to warm things up

Full Story

KITCHEN BACKSPLASHESHow to Choose a Backsplash for Your Granite Counters

If you’ve fallen for a gorgeous slab, pair it with a backsplash material that will show it at its best

Full Story

BATHROOM DESIGNSee the Clever Tricks That Opened Up This Master Bathroom

A recessed toilet paper holder and cabinets, diagonal large-format tiles, frameless glass and more helped maximize every inch of the space

Full Story

User

Jon1270

Related Professionals

Maywood Cabinets & Cabinetry · Newcastle Cabinets & Cabinetry · Tooele Cabinets & Cabinetry · Escondido Carpenters · Franklin Park Carpenters · Killeen Carpenters · Alpine Flooring Contractors · Avondale Flooring Contractors · Hazleton Flooring Contractors · Kendall West Flooring Contractors · Land O' Lakes Flooring Contractors · Little Rock Flooring Contractors · South Lake Tahoe Flooring Contractors · Richfield Furniture & Accessories · Carson Furniture & Accessoriesbrickeyee

kmealy

glimmOriginal Author

brickeyee

sombreuil_mongrel