How to finish my pine beadboard

matt_m

13 years ago

Related Stories

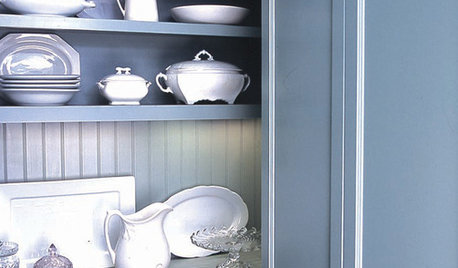

REMODELING GUIDESThe Timeless Elegance of Beadboard

Classic Wall Paneling Adds Instant Beach Cottage Charm

Full Story

REMODELING GUIDES8 Great Ways to Use Beadboard

Grooved Paneling Works Wonders on Backsplash, Bookshelf, Ceiling or Tub

Full Story

WALL TREATMENTSBeadboard Panels Offer a Shortcut to a Classic Style

Traditional touch: Change up plain bathroom walls with beaded hardwood planks and trim you can install yourself

Full Story

WALL TREATMENTSThese Are Not Your Grandfather’s Pine Walls

The knotty look went from popular to pariah in years past, but today’s designers are finding new and stylish ways to embrace it

Full Story

WOODDesign Workshop: Plywood as Finish

Trendproof your interior with this sensible guide to using this utilitarian material indoors

Full Story

TRADITIONAL HOMESHouzz Tour: Reviving a Half-Finished Farmhouse in New England

This 1790s foreclosure home was flooded and caved in, but the new homeowners stepped right up to the renovation

Full Story

Design Dilemma: Keep or Nix Knotty Pine?

Help a Houzz User Choose a Paint Color for a Cohesive Design

Full Story

CHRISTMASQuick and Easy Christmas Decor With Greens, Wreaths and Pine Cones

When you're short on time, focus on the basics to make your house festive and fragrant

Full Story

HOUZZ TVHouzz TV: Cool Reclaimed Wood Projects Fill a Craftsman’s Home

Using barn wood, beadboard and beams, this homeowner has crafted furnishings and features for his family’s Chicago home

Full Story

FLOORS11 Distinctive Finishes for Original Floorboards

Whether you go for glossy, painted or matte boards, make your wood floor the star

Full StoryMore Discussions

brickeyee

amrad

Related Professionals

Crestline Cabinets & Cabinetry · Lakeside Cabinets & Cabinetry · Radnor Cabinets & Cabinetry · Atwater Carpenters · Golden Glades Carpenters · King of Prussia Carpenters · Ridgewood Carpenters · The Hammocks Carpenters · Kirkwood Flooring Contractors · Topeka Flooring Contractors · Willoughby Flooring Contractors · Duluth Furniture & Accessories · Roseville Furniture & Accessories · Surprise Furniture & Accessories · Chino Hills Furniture & Accessoriesmatt_mOriginal Author

brickeyee

bobismyuncle