Finish for butcher block countertops -- NOT for cutting

pasigal

15 years ago

Related Stories

KITCHEN DESIGNButcher Block Makes the Cut for Holiday Kitchen Prep

Countertops and cutting boards will likely take a beating over the holidays. These butcher blocks have the chops to perform under pressure

Full Story

WOODWORKINGHow to Clean and Care for Your Butcher Block

Keep butcher block counters and boards looking sharp as a knife — and sanitized for safe food prep — with this advice from a pro woodworker

Full Story

KITCHEN DESIGNKitchen Counters: Try an Integrated Cutting Board for Easy Food Prep

Keep knife marks in their place and make dicing and slicing more convenient with an integrated butcher block or cutting board

Full Story

KITCHEN DESIGNNew This Week: 4 Surprising Backsplash and Countertop Pairings

Make your kitchen workspace stand out with colored ceramic tile, back-painted glass, butcher block and more

Full Story

KITCHEN COUNTERTOPSWalk Through a Granite Countertop Installation — Showroom to Finish

Learn exactly what to expect during a granite installation and how to maximize your investment

Full Story

CONTRACTOR TIPSContractor Tips: Countertop Installation from Start to Finish

From counter templates to ongoing care, a professional contractor shares what you need to know

Full Story

TINY HOUSESAdventure Seekers Hit the Road in a Cozy School Bus Home

Wood floors, butcher block countertops, custom furnishings and LED lights make life on the road feel like just another stylish day at home

Full Story

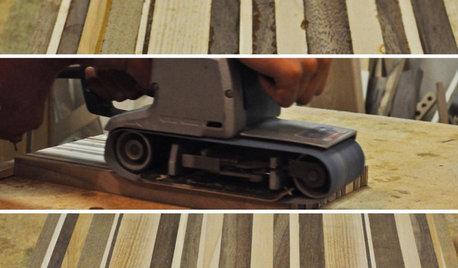

DIY PROJECTSFashion a High-Quality Cutting Board From Scrap Wood

Waste not, want not. This DIY project saves scraps from the landfill, hones your woodworking skills and produces a gorgeous kitchen piece

Full Story

KITCHEN DESIGN3 Steps to Choosing Kitchen Finishes Wisely

Lost your way in the field of options for countertop and cabinet finishes? This advice will put your kitchen renovation back on track

Full Story

KITCHEN DESIGN5 Favorite Granites for Gorgeous Kitchen Countertops

See granite types from white to black in action, and learn which cabinet finishes and fixture materials pair best with each

Full Story

bobismyuncle

pasigalOriginal Author

Related Professionals

Cypress Lake Carpenters · Franklin Park Carpenters · Coto De Caza Carpenters · Belvedere Park Flooring Contractors · Beverly Flooring Contractors · Bolingbrook Flooring Contractors · Chula Vista Flooring Contractors · Little Rock Flooring Contractors · Middleburg Flooring Contractors · St. Louis Flooring Contractors · Swampscott Flooring Contractors · Fayetteville Furniture & Accessories · Roswell Furniture & Accessories · Walnut Creek Furniture & Accessories · North New Hyde Park Handymanbobismyuncle

pasigalOriginal Author

bobismyuncle