Pics of my pressed wood computer desks!

jayjay_teacher

15 years ago

Related Stories

WORKING WITH PROSHow to Commission Custom Wood Furnishings

Can't find just the right table, shelf, desk or what have you? It's woodworkers to the rescue

Full Story

MOST POPULARGet Ready for the Smart Coffee Table

Intelligent tables with touch screens are reaching the consumer market, with all the power of personal computers and more

Full Story

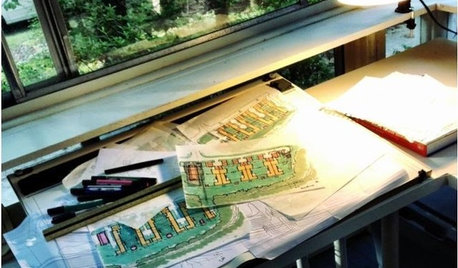

HOME OFFICESArchitects, Show Us: What's on Your Desk Right Now?

We'd love a peek at where your design ideas are brewing today

Full Story

HOME OFFICESExpert Talk: 11 Desk Designs That Really Work It

Boring or inadequate desks don't cut it for productivity in a home office. File these desk designs and expert insight under "To Do"

Full Story

HOME OFFICESHealthy Home: 8 Ways to Add a Standing Desk

Check out these options for doing less sitting during your screen, work and craft time

Full Story

HOME OFFICESA Desk for Every Home Office

To keep your work energized, a great desk is key. One of these 17 styles — from modern to vintage, sleek to salvaged — will work beautifully

Full Story

WHITE KITCHENS4 Dreamy White-and-Wood Kitchens to Learn From

White too bright in your kitchen? Introduce wood beams, countertops, furniture and more

Full Story

HOUZZ TOURSHouzz Tour: Laid-Back Comfort in the New York Woods

Expanded for a family, this unpretentious cabin puts a fresh face on rustic sensibility

Full Story

ECLECTIC HOMESHouzz Tour: Rebooting a 1930s Bungalow in 3 Days

A design team mixes old and new to upgrade a computer science teacher's home in a flash

Full Story

HOME OFFICES8 Twists on the Guest Room-Office Combo

In these clever spaces, the TV or computer can play while company's away

Full Story

MongoCT

User

Related Professionals

West Freehold Cabinets & Cabinetry · Carol City Carpenters · Tucson Carpenters · American Fork Flooring Contractors · Cutlerville Flooring Contractors · Freeport Flooring Contractors · Livonia Flooring Contractors · Monroe Flooring Contractors · Sachse Flooring Contractors · Taunton Flooring Contractors · Brooklyn Furniture & Accessories · Frisco Furniture & Accessories · Jacksonville Furniture & Accessories · Wichita Furniture & Accessories · Asheville Furniture & AccessoriesJon1270

jayjay_teacherOriginal Author

mogator88

jayjay_teacherOriginal Author

jbranch

bobismyuncle