Cabinet boxes- does joinery matter? $$ ?

jaydubya

12 years ago

Related Stories

INSIDE HOUZZHow Much Does a Remodel Cost, and How Long Does It Take?

The 2016 Houzz & Home survey asked 120,000 Houzzers about their renovation projects. Here’s what they said

Full Story

REMODELING GUIDESThe Good House: Little Design Details That Matter

Tailored trim, cool counters and a nice weighty door — such details add so much to how a home feels to the people inside

Full Story

FUN HOUZZ10 Truly Irritating Things Your Partner Does in the Kitchen

Dirty dishes, food scraps in the sink — will the madness ever stop?

Full Story

KITCHEN DESIGNHow Much Does a Kitchen Makeover Cost?

See what upgrades you can expect in 3 budget ranges, from basic swap-outs to full-on overhauls

Full Story

REMODELING GUIDESBathroom Workbook: How Much Does a Bathroom Remodel Cost?

Learn what features to expect for $3,000 to $100,000-plus, to help you plan your bathroom remodel

Full Story

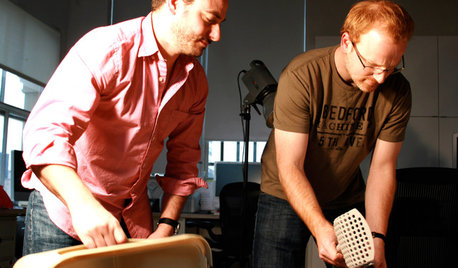

TASTEMAKERSModko Litter Boxes Address the Mess

A design duo has reinvented the much-maligned cat box, with an award-winning result

Full Story

HOME OFFICESYou Can Kick That Ugly Filing Cabinet to the Curb

When you’re ready to break out of the gray metal box, consider these creative options for storing your files

Full Story

LIFEGet the Scoop on High-Design Litter Boxes

Unavoidable doesn't have to mean unpleasant; cats and guardians alike will purr over these terrific design solutions for the litter box

Full Story

FURNITURE12 Sofa Colors That Won't Box You In

With any of these colors as a base, you can change your decor as often as you change your mind

Full StoryMore Discussions

Jon1270

jaydubyaOriginal Author

Related Professionals

Parsippany Cabinets & Cabinetry · Milford Mill Cabinets & Cabinetry · Enumclaw Carpenters · North Hollywood Carpenters · Sunnyvale Carpenters · Manteca Flooring Contractors · Redmond Flooring Contractors · San Rafael Flooring Contractors · Taunton Flooring Contractors · Rochester Furniture & Accessories · Fargo Furniture & Accessories · Maplewood Furniture & Accessories · Carpinteria Furniture & Accessories · Fish Hawk Handyman · North New Hyde Park HandymanJon1270

John Liu

User

brickeyee

jaydubyaOriginal Author

Jon1270

brickeyee