Blade size

urlee

14 years ago

Related Stories

HOUSEKEEPINGHow and Why You Should Clean Your Garden Tools

Avoid rust and extend the life and effectiveness of your blades and spades with these expert tips

Full Story

GARDENING GUIDESGreat Design Plant: Elymus Hystrix Thrives in Shade

Plant eastern bottlebrush grass in eastern U.S. woodlands or shade gardens for midsummer flower heads and blue-gray arching grass blades

Full Story

DECORATING GUIDESAre Ceiling Fans the Kiss of Death for Design?

Ceiling fans get a bad rap for being clunky and outdated, but these streamlined styles and a bevy of pros beg to differ

Full Story

REMODELING GUIDESFinishing Touches: Pro Tricks for Installing Fixtures in Your Tile

Cracked tile, broken drill bits and sloppy-looking fixture installations? Not when you follow these pro tips

Full Story

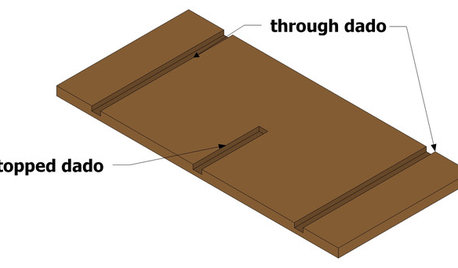

DESIGN DICTIONARYDado

Channel some support for shelves and cabinets with a dado groove in a board

Full Story

PRODUCT PICKSGuest Picks: The Well-Stocked Starter Kitchen

We’ve got all the kitchen basics and tableware you need (or that recent grad needs) to make cooking a joy

Full Story

TRADITIONAL STYLEFarmhouse Style: Windmill Power Comes Around Again

Windmills helped win the West. Today these hardworking features are still winning our hearts

Full Story

DECORATING GUIDESPaper Chase: Wallpaper Through the Ages to Today

Get on a decorating roll with a wall covering that's been around for centuries but comes in more exciting designs than ever

Full Story

HOLIDAYSVintage Sleds Bring a Dash of Winter Nostalgia

Antique sleds add a rustic touch to holiday decor — and can evoke fond memories too

Full Story

GRASSESHow to Rock a Lawn

Weekend Project: The key to healthy grass begins with the soil. If turf works for you, here’s how to fix it and keep it looking its best

Full StorySponsored

Columbus Area's Luxury Design Build Firm | 17x Best of Houzz Winner!

More Discussions

brickeyee

User

Related Professionals

Christiansburg Cabinets & Cabinetry · Whitehall Cabinets & Cabinetry · Cedar Park Carpenters · Coconut Grove Carpenters · Glendale Heights Carpenters · Kissimmee Carpenters · Arlington Flooring Contractors · Dorchester Flooring Contractors · Greenville Flooring Contractors · South Lake Tahoe Flooring Contractors · South Plainfield Flooring Contractors · Midland Furniture & Accessories · Portland Furniture & Accessories · Ventura Furniture & Accessories · Encinitas Furniture & AccessoriesurleeOriginal Author

brickeyee

urleeOriginal Author

urleeOriginal Author

brickeyee

urleeOriginal Author

urleeOriginal Author

User

urleeOriginal Author