bit for molding?

blufish

16 years ago

Related Stories

KITCHEN DESIGN9 Molding Types to Raise the Bar on Your Kitchen Cabinetry

Customize your kitchen cabinets the affordable way with crown, edge or other kinds of molding

Full Story

REMODELING GUIDESCrown Molding: Is It Right for Your Home?

See how to find the right trim for the height of your ceilings and style of your room

Full Story

REMODELING GUIDESFrame Your Views With Great Moldings and Casings

How to Work With Trim to Give Your Space Depth and Interest

Full Story

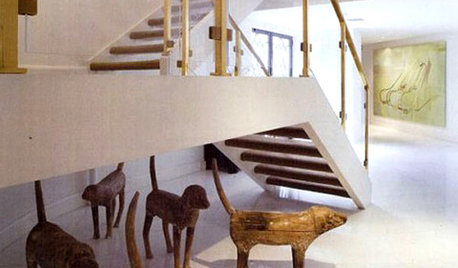

ARTExpert Talk: Sculpture Helps Rooms Break the Mold

Pro designers explain how sculpture can bring interiors to a higher level of design

Full Story

BRICK9 Ideas for Brick That Break the Mold

Bricks are as beautiful as they are useful, as these out-of-the-ordinary designs reveal

Full Story

COLOREvery Room Needs a Little Bit of Black

‘I’ve been 40 years discovering that the queen of all colors was black.’ — Pierre-Auguste Renoir

Full Story

KITCHEN DESIGNKitchen of the Week: Pushing Boundaries in a San Francisco Victorian

If the roll-up garage door doesn’t clue you in, the blue cabinets and oversize molding will: This kitchen is no ordinary Victorian galley

Full Story

REMODELING GUIDESHow to Size Interior Trim for a Finished Look

There's an art to striking an appealing balance of sizes for baseboards, crown moldings and other millwork. An architect shares his secrets

Full Story

KITCHEN WORKBOOK15 Elements of a Traditional Kitchen

Small details take center stage with decorative moldings, glazed finishes, raised panels and more

Full StoryMore Discussions

sombreuil_mongrel

User

Related Professionals

New Castle Cabinets & Cabinetry · Roanoke Cabinets & Cabinetry · Universal City Cabinets & Cabinetry · Leander Carpenters · Cartersville Flooring Contractors · Chelsea Flooring Contractors · Cutlerville Flooring Contractors · Everett Flooring Contractors · Faribault Flooring Contractors · Freeport Flooring Contractors · Hudson Flooring Contractors · Oro Valley Flooring Contractors · West Bend Flooring Contractors · Springdale Furniture & Accessories · North Bellmore Furniture & Accessoriesbobismyuncle

blufishOriginal Author

Jon1270

blufishOriginal Author

Jon1270

blufishOriginal Author