Anyone have idea on how to load test floating shelves?

youngdeb

17 years ago

Featured Answer

Sort by:Oldest

Comments (13)

kudzu9

17 years agoRelated Professionals

Forest Hills Cabinets & Cabinetry · Livingston Cabinets & Cabinetry · Tooele Cabinets & Cabinetry · Parsippany Carpenters · Sudbury Carpenters · Albuquerque Flooring Contractors · Cincinnati Flooring Contractors · Elgin Flooring Contractors · Fairfax Flooring Contractors · Faribault Flooring Contractors · Honolulu Flooring Contractors · Fullerton Flooring Contractors · Milwaukee Furniture & Accessories · St. Louis Furniture & Accessories · Tulsa Furniture & Accessoriesericwi

17 years agoJon1270

17 years agobrickeyee

17 years agoericwi

17 years agoron6519

17 years agoyoungdeb

17 years agoJon1270

17 years agoyoungdeb

17 years agoJon1270

17 years agobrickeyee

17 years agoJuliet Hurley

3 years ago

Related Stories

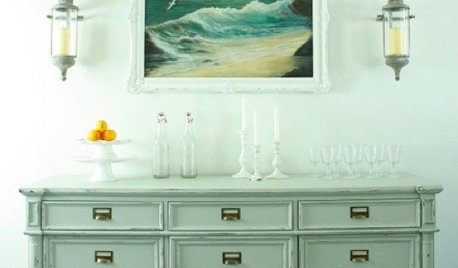

MOST POPULAR8 Beautiful Ideas for Floating Shelves

Get clean-lined storage and display on walls, over windows and in nooks using versatile floating shelving

Full Story

LAUNDRY ROOMSThe Cure for Houzz Envy: Laundry Room Touches Anyone Can Do

Make fluffing and folding more enjoyable by borrowing these ideas from beautifully designed laundry rooms

Full Story

MUDROOMSThe Cure for Houzz Envy: Mudroom Touches Anyone Can Do

Make a utilitarian mudroom snazzier and better organized with these cheap and easy ideas

Full Story

KITCHEN DESIGNThe Cure for Houzz Envy: Kitchen Touches Anyone Can Do

Take your kitchen up a notch even if it will never reach top-of-the-line, with these cheap and easy decorating ideas

Full Story

STORAGE5 Tips for Lightening Your Closet’s Load

Create more space for clothes that make you look and feel good by learning to let go

Full Story

BUDGET DECORATINGThe Cure for Houzz Envy: Entryway Touches Anyone Can Do

Make a smashing first impression with just one or two affordable design moves

Full Story

DECORATING GUIDESThe Cure for Houzz Envy: Dining Room Touches Anyone Can Do

Get a decorator-style dining room on the cheap with inexpensive artwork, secondhand furniture and thoughtful accessories

Full Story

HOME OFFICESThe Cure for Houzz Envy: Home Office Touches Anyone Can Do

Borrow these modest design moves to make your workspace more inviting, organized and personal

Full Story

SHELVESFloating Shelves: Minimal Design, Maximum Flexibility

Spare your walls with a shelf that holds an ever-changing collection of the stuff you love

Full Story

ARCHITECTURE21 Creative Ways With Load-Bearing Columns

Turn that structural necessity into a design asset by adding storage, creating zones and much more

Full StoryMore Discussions

Jon1270