Orbital Sander Troubles

CEFreeman

12 years ago

Related Stories

DECORATING GUIDESSpell It Out: Words of Inspiration for Your House

A favorite quote can enhance a room the way an inspiring idea engages your mind. Here’s how to add word power to your interiors

Full Story

HOUZZ TOURSMy Houzz: Bold Wallpaper Kicks Up a Century-Old Craftsman

Design risks pay off in a Seattle bungalow that combines fearless patterns with subtler colors and a sophisticated practicality

Full Story

GREAT HOME PROJECTSWhat to Know Before Refinishing Your Floors

Learn costs and other important details about renewing a hardwood floor — and the one mistake you should avoid

Full Story

FLOORS10 Ways to Make the Most of Your Home’s Original Floors

Save yourself the cost of replacing your old floorboards with these tips for a new finish

Full Story

WOODWORKINGHow to Clean and Care for Your Butcher Block

Keep butcher block counters and boards looking sharp as a knife — and sanitized for safe food prep — with this advice from a pro woodworker

Full Story

DECORATING GUIDESDIY Project: Sit Pretty with Mismatched Chairs

Create a one-of-a-kind dining set from a collection of cast-offs

Full Story

ACCESSORIESWhy You Should Forget About the Usual Coffee Table

Think in smaller multiples for a stylish and functional alternative to that monster table in the middle of the room

Full Story

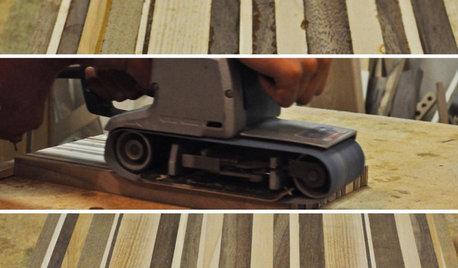

DIY PROJECTSFashion a High-Quality Cutting Board From Scrap Wood

Waste not, want not. This DIY project saves scraps from the landfill, hones your woodworking skills and produces a gorgeous kitchen piece

Full Story

COLORFUL HOMESHouzz Tour: Splashy, Sustainable Shack in São Paulo

An abandoned home gets a second chance as a sustainable weekend dwelling for a Brazilian couple in the design industry

Full Story

DIY PROJECTS14 Power Tools for the Home Shop

Want the thrill of building it yourself? These "big guns" help the handy homeowner tackle just about any job

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

More Discussions

sombreuil_mongrel

CEFreemanOriginal Author

Related Professionals

Lockport Cabinets & Cabinetry · Whitehall Cabinets & Cabinetry · Arlington Carpenters · Ridgewood Carpenters · Federal Way Flooring Contractors · Fort Lauderdale Flooring Contractors · Homestead Flooring Contractors · Monrovia Flooring Contractors · North Tustin Flooring Contractors · Temple Terrace Flooring Contractors · Brooklyn Furniture & Accessories · Madison Furniture & Accessories · Memphis Furniture & Accessories · Memphis Furniture & Accessories · Topeka Furniture & Accessoriesbrickeyee

bobismyuncle

brickeyee

CEFreemanOriginal Author

brickeyee