Cutting boards

wlg2_2

18 years ago

Related Stories

SHOP HOUZZShop Houzz: Save on Cutting Boards, Cheese Boards and Knives

Up to 60% off everything you need to chop, slice, carve and serve

Full Story0

KITCHEN DESIGNKitchen Counters: Try an Integrated Cutting Board for Easy Food Prep

Keep knife marks in their place and make dicing and slicing more convenient with an integrated butcher block or cutting board

Full Story

PRODUCT PICKSGuest Picks: Chop Chop! 20 Cutting Boards Too Good to Miss

Any way you slice it, these cutting boards, chopping blocks and serving boards are both artful and practical

Full Story

SHOP HOUZZShop Houzz: Cutting Boards That Won’t Leave You Bored

Serve up excitement with your next spread, with these unique cheese and cutting boards

Full Story0

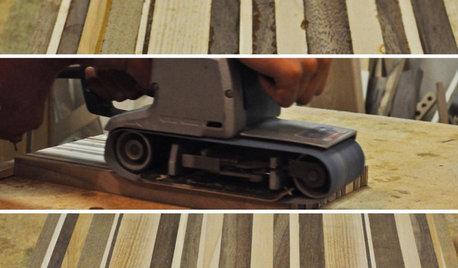

DIY PROJECTSFashion a High-Quality Cutting Board From Scrap Wood

Waste not, want not. This DIY project saves scraps from the landfill, hones your woodworking skills and produces a gorgeous kitchen piece

Full Story

KITCHEN DESIGNButcher Block Makes the Cut for Holiday Kitchen Prep

Countertops and cutting boards will likely take a beating over the holidays. These butcher blocks have the chops to perform under pressure

Full Story

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

KITCHEN DESIGNClever Extras for a Perfectly Personalized Kitchen Sink

Streamline cooking prep and cleanup with integrated sink racks, baskets, inventive cutting boards and more

Full Story

HOME TECHCook Smarter With New Wi-Fi Kitchen Gadgets

Whip up meals with high-tech help, thanks to a phone-connected oven and teakettle, plus a web-surfing cutting board

Full Story

SHOP HOUZZShop Houzz: Beautiful Wood Chopping Blocks

No more scratched counters — and these wood cutting boards are beautiful enough for the table too

Full Story0

olphart

sharon_sd

Related Professionals

Kaneohe Cabinets & Cabinetry · White Center Cabinets & Cabinetry · Idaho Carpenters · Mission Viejo Carpenters · South Miami Carpenters · Sudbury Carpenters · Eldersburg Flooring Contractors · Gilroy Flooring Contractors · Stevens Point Flooring Contractors · Tewksbury Flooring Contractors · Westlake Flooring Contractors · Greenville Furniture & Accessories · Peachtree City Furniture & Accessories · Hilton Head Island Furniture & Accessories · Northridge Furniture & Accessoriesolphart

kudzu9

MongoCT

brickeyee

kudzu9

Jon1270

MongoCT

corgilvr

antioch_frank

tap04