Need help with basic table

missykdiy

14 years ago

Related Stories

BATHROOM WORKBOOKStandard Fixture Dimensions and Measurements for a Primary Bath

Create a luxe bathroom that functions well with these key measurements and layout tips

Full Story

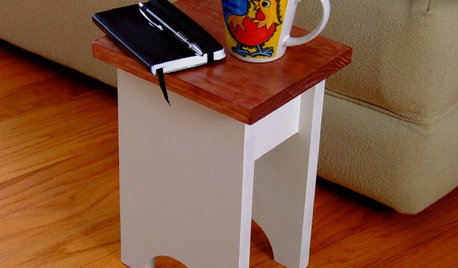

DIY PROJECTSNeat Little Project: Make a Basic Wood Stand

See how to make this handy table to hold your book, coffee or plant — then use the skills you learn to build something else later

Full Story

CONTAINER GARDENSContainer Garden Basics: How and When to Water Potted Plants

Confused about soil moisture, the best time to water and what watering device to use? This guide can help

Full Story

MOVINGYour First Home: Beautiful Basics and Multitaskers for Every Room

Here’s what to choose and what to avoid when outfitting a new house

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

ENTERTAININGEasy Hospitality: 3 Basics for Successful Hosting

Make guests comfortable even if resources are tight by getting these entertaining essentials down pat

Full Story

HOUZZ TOURSMy Houzz: A Basic Builder Home Gets the Glam Treatment

From blank canvas to decorated beauty, this home in Massachusetts changed a family's life in more ways than one

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

ACCESSORIESStyling Basics: 8 Favorite Accessories to Finish Your Space

Here's how to use these simple items to take your room to the next level

Full Story

DECKSDecking Materials Beyond Basic Lumber

Learn about softwoods, tropical hardwoods, composites and more for decks, including pros, cons and costs

Full Story

kudzu9

missykdiyOriginal Author

Related Professionals

Wyckoff Cabinets & Cabinetry · Arlington Carpenters · Round Rock Carpenters · Tacoma Carpenters · University City Flooring Contractors · Brooklyn Park Flooring Contractors · Gainesville Flooring Contractors · Harrisburg Flooring Contractors · Long Beach Flooring Contractors · Surprise Flooring Contractors · Indianapolis Furniture & Accessories · Philadelphia Furniture & Accessories · Alpharetta Furniture & Accessories · Sugar Hill Furniture & Accessories · Kendall Furniture & AccessoriesmissykdiyOriginal Author

kudzu9

Jon1270

sombreuil_mongrel

kudzu9

sombreuil_mongrel