Low Voltage from Portable Generator

loose_screw

12 years ago

Related Stories

SMALL SPACESHow Portability Can Make You Happier at Home

Downsizing your stuff and going for maximum mobility can actually make your home feel bigger and your life feel fuller

Full Story

DISASTER PREP & RECOVERYMore Power to You: How to Pick the Right Generator

If your home's electricity goes, don't let it take your necessities with it — keep systems running with this guide to backup power

Full Story

KITCHEN DESIGN20 Kitchen Must-Haves From Houzz Readers

We asked you to tell us your top kitchen amenities. See what popular kitchen features made the list

Full Story

MOST POPULAR15 Remodeling ‘Uh-Oh’ Moments to Learn From

The road to successful design is paved with disaster stories. What’s yours?

Full Story

REMODELING GUIDESGet What You Need From the House You Have

6 ways to rethink your house and get that extra living space you need now

Full Story

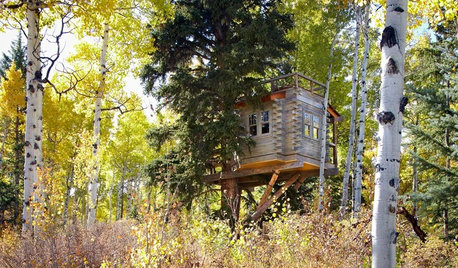

TREE HOUSESSwaying From Sleepovers to Dinner Parties in a Colorado Tree House

Folks of all ages have it made in the shade in this fun little house, thanks to electricity, a kitchenette and a rooftop deck

Full Story

ENTERTAININGHost a Laid-Back Girls’ Night in Your Own Backyard

Give the high heels a rest with a low-key, intimate gathering under the stars

Full Story

KITCHEN DESIGNKitchen Remodel Costs: 3 Budgets, 3 Kitchens

What you can expect from a kitchen remodel with a budget from $20,000 to $100,000

Full Story

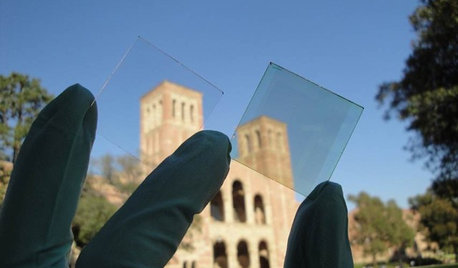

HOME TECHSmall Solar: Big Home Tech Trend in the Making

New technology enables everyday household objects to power themselves by harnessing natural light

Full Story

DECORATING GUIDES10 Retro Items Ripe for a Revival

Take a trip down memory lane through a world of innovative items from the past

Full StoryMore Discussions

Ron Natalie

loose_screwOriginal Author

Related Professionals

Cibolo General Contractors · Bryn Mawr-Skyway General Contractors · Oxon Hill General Contractors · Rancho Santa Margarita General Contractors · South Windsor General Contractors · Waimalu General Contractors · Wyomissing General Contractors · Attleboro Solar Energy Systems · Benicia Solar Energy Systems · Danville Solar Energy Systems · Old Saybrook Solar Energy Systems · Quincy Solar Energy Systems · Rosamond Solar Energy Systems · Pasadena Home Automation & Home Media · St. Johns Home Automation & Home Mediaionized_gw

bus_driver

enigma_2

loose_screwOriginal Author

enigma_2

brickeyee