Junction Box Grounding with 6AWG Splice

kevin1900

10 years ago

Related Stories

GARDENING AND LANDSCAPINGSpring Patio Fix-Ups: 6 Ways to Light Your Outdoor Room

Let the good times roll well into the evening with string lights, sconces, pendants and more to illuminate your patio or deck

Full Story

GREEN BUILDINGWorld of Design: The Joy of Moss and Its Modern Uses

This great design plant is 400 million years in the making. See how it’s inspiring art, soothing spaces and building design

Full Story

REMODELING GUIDES7 Bad Things Your Home May Be Hiding

What you don't know about your home could cost you during a remodel. Here's what to plan for

Full Story

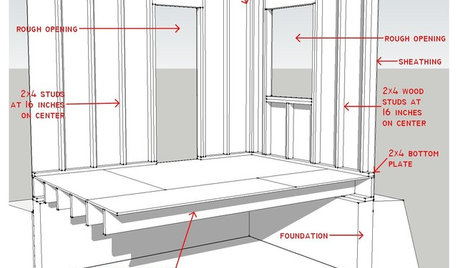

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

CONTRACTOR TIPSYour Complete Guide to Building Permits

Learn about permit requirements, the submittal process, final inspection and more

Full Story

STORAGETap Into Stud Space for More Wall Storage

It’s recess time. Look to hidden wall space to build a nook that’s both practical and appealing to the eye

Full Story

GREAT HOME PROJECTSPower to the People: Outlets Right Where You Want Them

No more crawling and craning. With outlets in furniture, drawers and cabinets, access to power has never been easier

Full Story

CEILINGSAdd a Touch of Elegance With a Ceiling Medallion

Installed with adhesive and often less than $100, this decorative detail makes an impact

Full Story

BATHROOM DESIGNWarm Up Your Bathroom With Heated Floors

If your bathroom floor is leaving you cold, try warming up to an electric heating system

Full Story

MOST POPULAR9 Real Ways You Can Help After a House Fire

Suggestions from someone who lost her home to fire — and experienced the staggering generosity of community

Full Story

Ron Natalie

kevin1900Original Author

Related Professionals

Murraysville General Contractors · Clinton General Contractors · Medway General Contractors · Rohnert Park General Contractors · Rosemead General Contractors · Wheaton General Contractors · Winfield General Contractors · Vienna Handyman · North New Hyde Park Handyman · Brookline Home Automation & Home Media · Chicago Home Automation & Home Media · Rowland Heights Home Automation & Home Media · Tamiami Home Automation & Home Media · Weatherford Home Automation & Home Media · Walnut Creek Home Automation & Home MediaRon Natalie

weedmeister

weedmeister

Ron Natalie

kevin1900Original Author

Ron Natalie

kevin1900Original Author