solutions for old home with aluminum wiring

tikka_masala

13 years ago

Related Stories

HOME TECH6 Sound Solutions for the iPhone Home

Listen up: An iPhone and one of these stylish audio systems let your music look as good as it sounds

Full Story

HOUZZ TVHouzz TV: See a Funky Beach Home Made From Old Streetcars

A bold color palette zaps life into a Santa Cruz, California, home built out of two streetcars from the early 1920s

Full Story

STORAGEHow a Pro Organizer Improved Her Own Home’s Storage

New kitchen drawers, an upgraded laundry workspace and extra garage storage create a more functional, organized space

Full Story

GREAT HOME PROJECTSHow to Bring Out Your Home’s Character With Trim

New project for a new year: Add moldings and baseboards to enhance architectural style and create visual interest

Full Story

HOUZZ TVRetired Houston Couple Replaces Starter Home With Forever Home

See how the Elders built their dream home while preserving the memory of the home they lived in for nearly 4 decades

Full Story

PATIOSPatio Details: A Custom Aluminum Arbor Cools Things Down in Texas

Panels in the roof have leaf pattern cutouts that create dappled shade and a calm, relaxed ambience

Full Story

ECLECTIC HOMESHouzz Tour: Remodel Celebrates Northwest Home’s Vintage Style

A creative couple brings back the original charm of a 1920s home and makes it a guesthouse and studio

Full Story

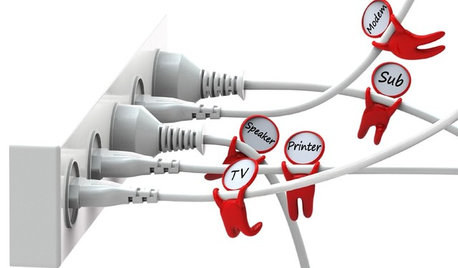

MORE ROOMSOn Trend: Smart Solutions for Cords

Show those cables and wires who's boss with these clever solutions for the home office

Full Story

SMALL HOMESHouzz Tour: Old Garage in Paris Becomes a Family Loft

A single source of natural light goes far in this 700-square-foot home for a couple and their 2 kids

Full Story

ACCESSORIESHow to Hide Those Messy Wires

Untangle Yourself From Ugly Electrical Cords With a Few Tricks and Accessories

Full Story

Billl

texasredhead

Related Professionals

Champaign General Contractors · Fridley General Contractors · Greenville General Contractors · Marysville General Contractors · Milton General Contractors · Oxon Hill General Contractors · Pepper Pike General Contractors · West Lafayette General Contractors · Madison Solar Energy Systems · Peabody Solar Energy Systems · Atlanta Home Automation & Home Media · Chattanooga Home Automation & Home Media · Gages Lake Home Automation & Home Media · Safety Harbor Home Automation & Home Media · East Setauket Home Automation & Home Mediahrajotte

brickeyee

texasredhead

netlos

brickeyee