ser 2-2-2-4 for 100 amp sub panel copper or aluminum

spencer_electrician

18 years ago

Featured Answer

Sort by:Oldest

Comments (9)

petey_racer

18 years agonormel

18 years agoRelated Professionals

Delhi Electricians · Lake Nona Electricians · Dover General Contractors · Forest Hills General Contractors · Greensburg General Contractors · Los Lunas General Contractors · Merritt Island General Contractors · Niles General Contractors · Parkville General Contractors · Ravenna General Contractors · Rolling Hills Estates General Contractors · Bridgeport Solar Energy Systems · Randolph Solar Energy Systems · Titusville Solar Energy Systems · Rosamond Solar Energy Systemsmikie_gw

18 years agopetey_racer

18 years agopetey_racer

17 years agobus_driver

17 years agoitsunclebill

17 years agoHU-607168021

2 years ago

Related Stories

CONTEMPORARY HOMESHouzz Tour: 2 Wings for 3 Generations on a Vermont Lake

An extended family enjoys a spacious waterfront home influenced by farmhouses and Japanese architecture

Full Story

PAINTINGKnotty to Nice: Painted Wood Paneling Lightens a Room's Look

Children ran from the scary dark walls in this spare room, but white paint and new flooring put fears and style travesties to rest

Full Story

MATERIALSAn Architect Shares His Go-To Materials

Aluminum doors, porcelain tiles, polished concrete. Here are the features and finishes this professional returns to time and again

Full Story

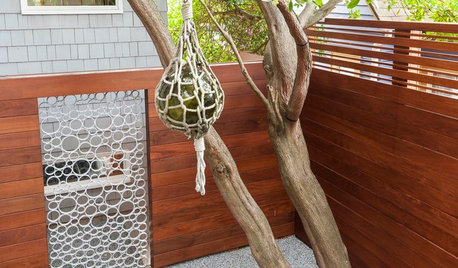

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

HOUZZ TOURSMy Houzz: A Classic Midcentury Home Wrapped in Windows

A couple's 4-year restoration and renovation results in a bright look for their wood-paneled house in New York

Full Story

SMALL KITCHENSHouzz Call: Show Us Your 100-Square-Foot Kitchen

Upload photos of your small space and tell us how you’ve handled storage, function, layout and more

Full Story

SMALL KITCHENSThe 100-Square-Foot Kitchen: Fully Loaded, No Clutter

This compact condo kitchen fits in modern appliances, a walk-in pantry, and plenty of storage and countertop space

Full Story

GREEN BUILDINGLet’s Clear Up Some Confusion About Solar Panels

Different panel types do different things. If you want solar energy for your home, get the basics here first

Full Story

WHITE KITCHENS4 Dreamy White-and-Wood Kitchens to Learn From

White too bright in your kitchen? Introduce wood beams, countertops, furniture and more

Full Story

KITCHEN DESIGNNew This Week: 4 Kitchens That Embrace Openness and Raw Materials

Exposed shelves, open floor plans and simple materials make these kitchens light and airy

Full Story

electricalguru