Basement Finish. Sub Panel or no?

bakerz1

14 years ago

Related Stories

REMODELING GUIDESContractor Tips: Finish Your Basement the Right Way

Go underground for the great room your home has been missing. Just make sure you consider these elements of finished basement design

Full Story

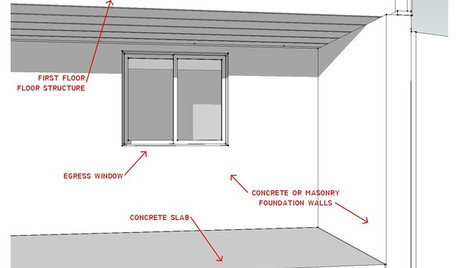

REMODELING GUIDESKnow Your House: The Steps in Finishing a Basement

Learn what it takes to finish a basement before you consider converting it into a playroom, office, guest room or gym

Full Story

PAINTINGKnotty to Nice: Painted Wood Paneling Lightens a Room's Look

Children ran from the scary dark walls in this spare room, but white paint and new flooring put fears and style travesties to rest

Full Story

REMODELING GUIDES11 Ways to Finesse Your Finished Basement

Make your hideaway more enjoyable, fun and suited to your style with these useful tips

Full Story

DECORATING GUIDESBeautiful Details: Wainscoting and Paneled Walls

Paneled Walls Add Substance and Style to Both Modern and Traditional Homes

Full Story

How to Update Cozy Wood Paneling

See how to give fresh life to once-retro woodsy wall coverings

Full Story

GREEN BUILDINGLet’s Clear Up Some Confusion About Solar Panels

Different panel types do different things. If you want solar energy for your home, get the basics here first

Full Story

KITCHEN DESIGN3 Steps to Choosing Kitchen Finishes Wisely

Lost your way in the field of options for countertop and cabinet finishes? This advice will put your kitchen renovation back on track

Full Story

DIY PROJECTSHow to Create Your Own Semicustom Media Wall

Don’t let the price of a custom built-in stop you. Put one together with ready-made pieces and a little finish help

Full Story

GREEN BUILDINGGoing Solar at Home: Solar Panel Basics

Save money on electricity and reduce your carbon footprint by installing photovoltaic panels. This guide will help you get started

Full Story

manhattan42

spencer_electrician

Related Professionals

Annandale General Contractors · Conneaut General Contractors · DeSoto General Contractors · Foothill Ranch General Contractors · Grand Junction General Contractors · Jamestown General Contractors · San Carlos Park General Contractors · University Park General Contractors · Vincennes General Contractors · Old Saybrook Solar Energy Systems · Weymouth Solar Energy Systems · New Lenox Solar Energy Systems · Sarasota Home Automation & Home Media · Westminster Home Automation & Home Media · East Cleveland Home Automation & Home MediaRon Natalie

spencer_electrician

bakerz1Original Author

Ron Natalie

normel

bakerz1Original Author