aluminum sill pans?

dgmarie

13 years ago

Featured Answer

Sort by:Oldest

Comments (18)

millworkman

13 years agodgmarie

13 years agoRelated Professionals

Madison Window Contractors · Two Rivers Window Contractors · Sherman Oaks Window Contractors · Westmont Window Contractors · Fountain Hills Interior Designers & Decorators · Garden Acres Interior Designers & Decorators · Bay City General Contractors · Champaign General Contractors · Elmont General Contractors · Ken Caryl General Contractors · Murrysville General Contractors · Panama City Beach General Contractors · Valley Stream General Contractors · Olathe Carpenters · Rantoul Carpentersdgmarie

13 years agokaib

13 years agodgmarie

13 years agodgmarie

13 years agoWindows on Washington Ltd

13 years agodavidgipson

11 years agommarse1

11 years agoWindows on Washington Ltd

11 years agodavidgipson

11 years agoWindows on Washington Ltd

11 years agobrickeyee

11 years agojdelano

2 years agoEast Bay 10

2 years agotoddinmn

2 years agojdelano

2 years ago

Related Stories

MATERIALSAn Architect Shares His Go-To Materials

Aluminum doors, porcelain tiles, polished concrete. Here are the features and finishes this professional returns to time and again

Full Story

KITCHEN DESIGNHow to Become Friends With the Kitchen Again

Get ready for cooking season with music, cookbooks, light, herbs in the window sill and more

Full Story

HOUSEKEEPINGHow to Clean Your Cookware So It Lasts

Avoid damage during everyday cleaning and stain scrubbing, with these tips for pots and pans made of popular materials

Full Story

FEEL-GOOD HOME8 Tips for Harmony in the Kitchen

Frustrated by the arguments that arise over kitchen duties? Check out these coping strategies

Full Story

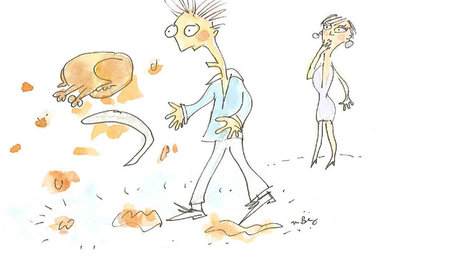

MOST POPULARThanksgiving Tales: When the Turkey Tanks

Houzz readers prove adept at snatching victory from the jaws of entertaining defeat

Full Story

WINDOWSHow to Replace Window Trim

For finishing new windows or freshening the old, window trim gives a polished look with less effort than you may think

Full Story

KITCHEN DESIGNPlay the Trading Game With Kitchen Storage and Views

Cabinets have their place, of course, but just imagine handling kitchen tasks with a glorious panorama for company

Full Story

BATHROOM DESIGNThe No-Threshold Shower: Accessibility With Style

Go curbless between main bath and shower for an elegant addition to any home

Full Story

KITCHEN STORAGEBoost Your Kitchen Storage With Pegboard on a Wall

Julia Child knew it: This budget-friendly material is a winner for wall organization

Full Story

KITCHEN STORAGEPulling Power: Clever Drawer Tactics for a Kitchen

It’s not how many drawers you have in your kitchen; it’s how they work for you

Full StorySponsored

More Discussions

Camden Greenlee