How far into the wall does a window go?

toolbabe

14 years ago

Related Stories

INSIDE HOUZZHow Much Does a Remodel Cost, and How Long Does It Take?

The 2016 Houzz & Home survey asked 120,000 Houzzers about their renovation projects. Here’s what they said

Full Story

DECORATING GUIDESGo for a Greenhouse Effect With an Exotic Conservatory

Cultivate a rarified hothouse feel with or without all-glass walls; these inspiration photos and product picks show you how

Full Story

LANDSCAPE DESIGNDoes Your Landscape Need a Little ‘Cosmic Latte’?

Beige — the color of the universe — can be both building block and backdrop in a contemporary garden

Full Story

KITCHEN DESIGNHow Much Does a Kitchen Makeover Cost?

See what upgrades you can expect in 3 budget ranges, from basic swap-outs to full-on overhauls

Full Story

REMODELING GUIDESBathroom Workbook: How Much Does a Bathroom Remodel Cost?

Learn what features to expect for $3,000 to $100,000-plus, to help you plan your bathroom remodel

Full Story

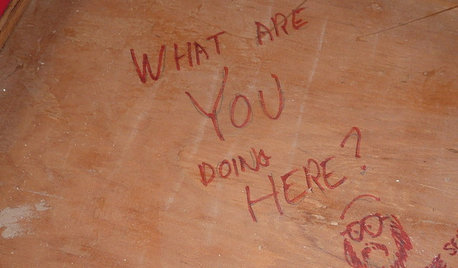

FUN HOUZZDoes Your Home Have a Hidden Message?

If you have ever left or found a message during a construction project, we want to see it!

Full Story

MOST POPULARWhen Does a House Become a Home?

Getting settled can take more than arranging all your stuff. Discover how to make a real connection with where you live

Full Story

FUN HOUZZ10 Truly Irritating Things Your Partner Does in the Kitchen

Dirty dishes, food scraps in the sink — will the madness ever stop?

Full Story

WINDOW TREATMENTSHow Low Should Your Drapes Go?

Hover, brush the floor or pool like Scarlett O'Hara's tears — we give you the lowdown on curtain length options

Full Story

HOME TECHHang Out With Friends All Day, Anywhere You Go

Connect with compadres or colleagues using always-on ambient video — consider it a free magic window for the home, the office or on the go

Full Story

East Bay 10

toolbabeOriginal Author

Related Professionals

Wilmington Window Contractors · Wichita Window Contractors · Artesia Window Contractors · Homestead Window Contractors · Santa Cruz Window Contractors · Spanaway Window Contractors · Sugarland Run Window Contractors · Webster Groves Window Contractors · Little Egg Harbor Twp Interior Designers & Decorators · Fremont General Contractors · Hamilton Square General Contractors · Troutdale General Contractors · Williamstown General Contractors · Woodland General Contractors · Valdosta CarpentersEast Bay 10

toolbabeOriginal Author

afsa

mcsbldr

toolbabeOriginal Author

toolbabeOriginal Author

toolbabeOriginal Author

millworkman