Andersen glass failure due to negative pressure

napagirl

17 years ago

Featured Answer

Sort by:Oldest

Comments (129)

Windows on Washington Ltd

8 years agoquasiexpert

8 years agoRelated Professionals

Castro Valley Window Contractors · Annapolis Window Contractors · Brooklyn Window Contractors · University Window Contractors · Littleton Window Contractors · Glen Burnie Window Contractors · Wilmette Window Contractors · Merriam Window Contractors · Charleston Interior Designers & Decorators · Arizona City General Contractors · Los Alamitos General Contractors · Palatine General Contractors · North Miami Beach Carpenters · Salisbury Carpenters · St. Johns CarpentersWindows on Washington Ltd

8 years agoquasiexpert

8 years agoWindows on Washington Ltd

8 years agonapagirl

8 years agoWindows on Washington Ltd

8 years agoquasiexpert

8 years agoMary Beerman

4 years agoWindows on Washington Ltd

4 years agoeedstang

4 years agodena_sue2000

4 years agooberon476

4 years agolast modified: 4 years agotoddinmn

4 years agodena_sue2000

4 years agoHU-227336430

4 years agoquasiexpert

4 years agolast modified: 4 years agoHU-255094469

4 years agodena_sue2000

4 years agoHU-387008398

4 years agoHU-449232683

4 years agoWindows on Washington Ltd

4 years agolast modified: 4 years agoHU-449232683

4 years agooberon476

4 years agolast modified: 4 years agoHU-449232683

4 years agoWindows on Washington Ltd

4 years agoKatho

3 years agoHU-171678280

3 years agolast modified: 3 years agooberon476

3 years agolast modified: 3 years agonapagirl

3 years agolast modified: 3 years agooberon476

3 years agolkbum_gw

3 years agooberon476

3 years agonapagirl

3 years agooberon476

3 years agoBrandon Conkins

3 years agoWindows on Washington Ltd

3 years agojennajp222

3 years agomillworkman

3 years agotoddinmn

3 years agomillworkman

3 years agoquasiexpert

3 years agoquasiexpert

3 years agoLorenzo Fernandez Jr.

3 years agomillworkman

3 years agoTom

2 years agoJoseph Voicheck

2 years agoWindows on Washington Ltd

2 years ago

Related Stories

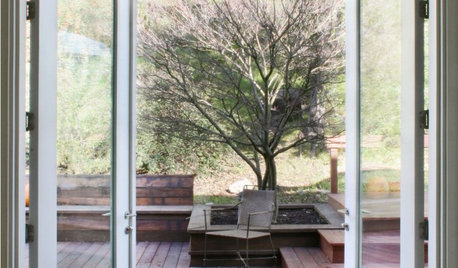

MOST POPULARFind the Right Glass Door for Your Patio

It’s more than just a patio door — it’s an architectural design element. Here’s help for finding the right one for your home and lifestyle

Full Story

HOME TECHThe Future of Home Automation: Cheap, Wearable and Mobile!

Look for smart watches and glasses that can control your smart-phone apps, which in turn automate your home equipment

Full Story

HOUZZ TOURSMy Houzz: Dive Into a Cajun Country Home With an Indoor Pool

Drenched in sunshine from a massive glass atrium roof, this newly redesigned Louisiana home works swimmingly

Full Story

SHOWERSTurn Your Shower Niche Into a Design Star

Clear glass surrounds have raised the design bar for details such as shampoo and soap shelves. Here are 4 standouts

Full Story

BATHROOM TILEQuick Fix: Repair Cracked Bathroom Grout

Banish an eyesore and safeguard your bathroom from water damage in 30 minutes or less with this DIY repair

Full Story

ARCHITECTURE4 Zurich Projects Build on High-Rise Livability

Generous landscaping, underground parking and terraces make these apartment complexes models of thoughtful housing

Full Story

LIFEWhy We Want a House With a Great View

Research shows that just looking at nature has powerful mental benefits. Here's how to get a boost — with or without a million-dollar view

Full Story

FURNITUREWhy It's OK to Hate Your New Custom Sofa

It takes time to get used to bold new furniture, but dry your tears — the shock can be good for you. Here's what to expect

Full Story

ENTERTAINING8 Stress-Busting Tips for Hosting Small Gatherings

Make entertaining easy with these ideas for casual get-togethers

Full Story

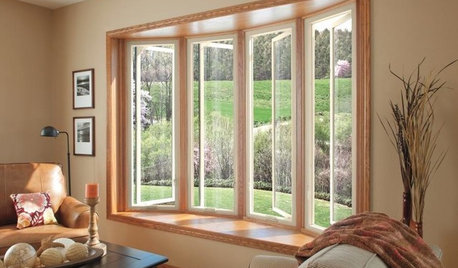

GREAT HOME PROJECTSUpgrade Your Windows for Beauty, Comfort and Big Energy Savings

Bid drafts or stuffiness farewell and say hello to lower utility bills with new, energy-efficient windows

Full Story

napagirlOriginal Author