Sistered joist fastening questions

ntruro

14 years ago

Related Stories

REMODELING GUIDESSurvive Your Home Remodel: 11 Must-Ask Questions

Plan ahead to keep minor hassles from turning into major headaches during an extensive renovation

Full Story

DIY PROJECTSThe Taming of the Screw

Learn the different types and uses of screws to pick the right kind for your next DIY or home improvement project

Full Story

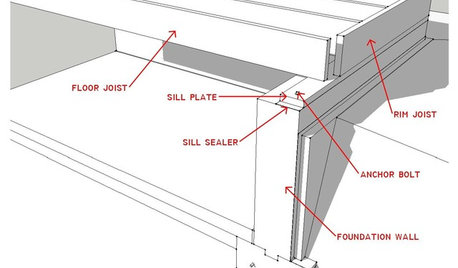

KNOW YOUR HOUSEKnow Your House: What Makes Up a Floor Structure

Avoid cracks, squeaks and defects in your home's flooring by understanding the components — diagrams included

Full Story

HOUZZ TOURSHouzz Tour: A Home Full of History and Surprise

Minnesota designer remodels a historic residence using traditional styles and techniques

Full Story

GARDENING AND LANDSCAPINGChoosing a Deck: Plastic or Wood?

Get the pros and cons of wood, plastic, composite and more decking materials, plus a basic price comparison

Full Story

MOST POPULARMy Houzz: Hip Midcentury Style for a Mom's Backyard Cottage

This 1-bedroom suite has everything a Texas mother and grandmother needs — including the best wake-up system money can't buy

Full Story

DECORATING GUIDESDecorating Secrets: Picture-Perfect Way to Hang Art

Save your drywall with these easy steps for hanging framed pieces

Full Story

DESIGN DETAILSDesign Workshop: The Modern Wall Base, 4 Ways

Do you really need baseboards? Contemporary design provides minimalist alternatives to the common intersection of floor and wall

Full Story

BATHROOM DESIGNThe Case for a Curbless Shower

A Streamlined, Open Look is a First Thing to Explore When Renovating a Bath

Full Story

REMODELING GUIDESWhat to Know Before You Tear Down That Wall

Great Home Projects: Opening up a room? Learn who to hire, what it’ll cost and how long it will take

Full Story

sierraeast

brickeyee

Related Professionals

Parkland Home Remodeling · Key Biscayne Kitchen & Bathroom Remodelers · Port Orange Kitchen & Bathroom Remodelers · Beloit General Contractors · Franklin General Contractors · Hammond General Contractors · Montclair General Contractors · Joppatowne General Contractors · Colorado Springs Painters · Columbus Painters · Boca Raton Painters · Cupertino Painters · Newton Painters · Sedona Painters · South Riding Paintersmacv

macv