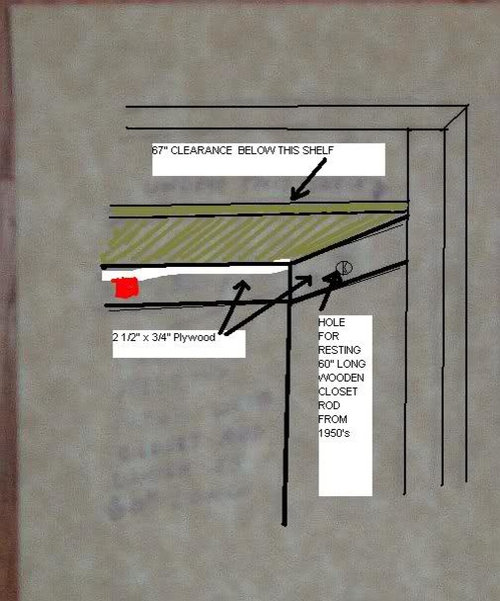

repair my collapsed closet rods

jally

12 years ago

Related Stories

STORAGE5 Tips for Lightening Your Closet’s Load

Create more space for clothes that make you look and feel good by learning to let go

Full Story

CLOSETSThe 15 Most Popular Closet Luxuries on Houzz

Turn distressing disarray into streamlined perfection with closet organizers and amenities like these

Full Story

MOST POPULARHow to Get the Closet of Your Dreams

Do you cringe every time you open your closet door? It may be time for a makeover

Full Story

ORGANIZINGSmart Solutions for Clothes Closets

The Hardworking Home: Explore these ways to store your clothes, shoes and accessories to make the most of your space

Full Story

CLOSETSHouzz Call: Is Your Closet a Storage Powerhouse?

We want to see how you are making the most of your closet storage areas. Post pictures and tell us how you’ve organized them

Full Story

CLOSETS9 Features That Are Popular in Closets Now

Design pros and popular Houzz photos highlight the looks that homeowners are loving in closets

Full Story

CLOSETSSpring-Cleaning Moves to Help You Feel Better About Your Closet

It’s possible to love your clothes storage space, no matter how small

Full Story

DECLUTTERINGGet It Done: Clean Out Your Bedroom Closet

You can do it. Sort, purge, clean — and luxuriate in all the extra space you’ll gain — with this motivating, practical how-to

Full Story

ORGANIZINGProfessional Tips for Organizing Your Clothes Closet

As summer draws to a close, get expert advice on editing and organizing your wardrobe

Full Story

CLOSETSHow to Style Your Closet (Almost) Like a Celeb

12 closet tips: Sorting, planning, lighting and styling make "What to Wear?" easier to answer

Full StoryMore Discussions

graywings123

jallyOriginal Author

Related Professionals

Albuquerque Kitchen & Bathroom Remodelers · Athens Kitchen & Bathroom Remodelers · Rancho Cordova Kitchen & Bathroom Remodelers · Rolling Hills Estates Kitchen & Bathroom Remodelers · Goodlettsville General Contractors · Chatsworth General Contractors · Summit General Contractors · Baton Rouge Painters · Danbury Painters · Euless Painters · Lakewood Painters · Oak Forest Painters · Park Ridge Painters · Sunrise Painters · Whittier PaintersjallyOriginal Author

sierraeast

sierraeast

brickeyee

GammyT

brickeyee

graywings123

brickeyee

graywings123

jallyOriginal Author

jallyOriginal Author

graywings123

sdello

brickeyee

jallyOriginal Author

graywings123

jallyOriginal Author

graywings123

jallyOriginal Author

graywings123

jallyOriginal Author

greg_2010

jallyOriginal Author