need help with roof truss

I have a 10' x 14' wood shed that I have converted to a small workshop.My problem is the lack of head room caused by the bottom cord of the trusses wich measures 6'6" from bottom of floor.I know these cords prevent the walls from spreading,but if I left the two on the ends could I cut the others?My other thought was to just make new ones higher up.Any help on this I would really appreciate,thanks.

Comments (32)

rjoh878646

15 years agoYou cannot cut any of the trusses without compromising the whole roof. If you cut the trusses I believe a load on the roof will cause it to cave in.

davidandkasie

15 years agoi have seen some tha tyou could make new ones higher, but others you MUST leave as they are.

this is a shed, and i doubt it has much roof load. i would think you could do it as long as you put new ones in higher. we have several wood sheds and all of ours have them at 7' with the ridge being around 8.5-9' above floor level.

i doubt they are real trusses you have, most likely it is just rafters. is it possible you cna post a picture or two? if you could it would give folks a better idea of whether it is possible.

Related Professionals

Bloomington General Contractors · Bowling Green General Contractors · Hartford General Contractors · Little Egg Harbor Twp General Contractors · Columbia Painters · Danbury Painters · Arnold Painters · Beach Park Painters · Jefferson City Painters · Lexington Painters · Northglenn Painters · Woodbury Painters · Castaic Painters · Kailua Painters · North Reading Painterstomslildeere

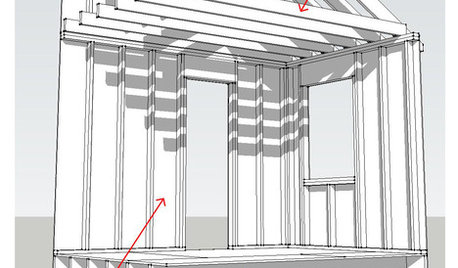

Original Author15 years agoI took some pics of the roof trusses ,the insulation is covering up the top part but it basically forms a triangle.I run two 2x4's higher up to mount light fixtures and I was hoping to set the ceiling to the same height.The bottom cord sets on the wall.They are 24" apart.I thought about cutting the bottom cord 6" out from the wall and then running them upwards parallel with the the roof up to my height and then join them in the middle.So the walls would still be tied all the way across.Thank you for all your help guys.

Here is a link that might be useful: truss

justnigel

15 years agoIf you're serious about this, get an engineer to design a new truss for you. I expect they'd spec some kind of a scissor truss. (You really do need to keep your walls tied together, and with respect, I don't think your idea in the post above is really up to the job. Or maybe I'm just not properly picturing what you're suggesting.)

This might be nuts, but how about lifting up the whole structure and building a 2' wall under the plate?

Nigel

snoonyb

15 years agoWe used to mfg. our own trusses, bolted together, before the era of pressed clamps,

That said, I would, at the height of 96-1/2" above the floor, install a horiz. 2x4 on each side of the existing

truss bolted thru with a single 3/8" bolt, creating a new bottom chord. As additional support, install a cripple jack from the bottom of the new bottom chord to the top plate, sistering the existing.

From the center of the bottom chord install a 2x4 between the two members, cut to fit to the ridge, attached with 2-16D's to the ridge and another 3/8" bolt at the bottom chord, creating a King post.

Then remove the existing bottom chord.tomslildeere

Original Author15 years agoThanks snoonyb,this was the answer i was hoping for.One question though,after I finish bolting a new bottom cord,can I cut the corresponding old one and use the wood for my cripple jacks if done one at a time?

This would save me alot of 2x4 waste.snoonyb

15 years agoNot until you have installed the new King post.

http://www.truss-frame.com/truss-glossary.htmltomslildeere

Original Author15 years agoThe rafters are 2x4 spanning 10'. Length of shed is 14'.As far as snow loads go I'm located in northeast ohio.The spacing is 24" on the truss.

tomslildeere

Original Author15 years agoDoes anyone think snoonyb's idea will not work?I am still taking suggestions.

mightyanvil

15 years agoHis description makes no sense to me.

Any design that raises the bottom chord will put additional moment into the rafter chords that they are not designed to take.

If this were a conventional system with rafters from the top plates to a ridge board there would be a way to raise the rafter ties but unfortunately it isn't.

Either replace the roof or raise the building up.

snoonyb

15 years ago"mightyanvil"

Let me clear this up for you, since you've elected to not direct question to me, but at me."Any design that raises the bottom chord will put additional moment into the rafter chords that they are not designed to take."

Perhaps you missed this:

"Posted by snoonyb (My Page) on Sun, Aug 31, 08 at 22:43""As additional support, install a cripple jack from the bottom of the new bottom chord to the top plate, sistering the existing."

Does that answer your question?

mightyanvil

15 years agoI responded to the OP because he asked a question about the feasibility of the truss you suggested; I have no reason to respond to you but now that you have asked, I will tell you that I don't understand your description.

The use of the term "cripple jack" (rafter, I assume) is confusing since by definition such a member would not touch a top plate but aside from that I don't see how the member would provide any more lateral stability to the walls than the existing intermediate horizontal chords do or what it would be "sistered to".

You shouldn't be surprised or offended that a written description of a non-standard truss would be difficult to understand. If you want to convince me and the OP that it will work you will probably need to post a sketch.

tomslildeere

Original Author15 years agoWhat I wanted really to know for sure was why this would not work.Would going with a 2x6 for the new bottom cord make any difference?

mightyanvil

15 years agotomslildeere

You asked a question and I'm just trying to answer it.

If you understand the description, either describe it in terms I can understand or post a diagram of it and I'll tell you what I think of it.

mightyanvil

15 years agotomslildeere

Here is what I can tell you from what I have seen here.

A "bottom chord" of a truss always sits on the reaction (support) point. In this case that would be the wall top plate.

If an intermediate horizontal chord is added between the mid points of the rafter chords, it is not a new "bottom chord". In fact, when the original bottom chord is removed, the structure is no longer a truss; it essentially becomes simple span rafters with a collar or rafter tie at he mid point of the rafters. This configuration puts additional bending moment into the mid point of the rafter that it is not designed to take under the maximum design loading. Depending on the actual height of the ridge and the snow load, the building code (or accepted engineering practice) might allow the new horizontal member to be installed 6" or 8" above the top plate but I can't be more specific without more information.

One problem with this condition is that the original rafter chords are not sitting on the wall top plate but on the original bottom chords at a point beyond the plane of the interior wall. This indirect connection detail must be resolved if the original bottom chord is removed.

If another member is installed directly under the original rafter chord from the top plate to a new collar tie/intermediate chord, it would resolve the rafter bottom connection problem but it would not relieve the overstress at the mid point of the original rafter chord. To do that it would have to reach the ridge and be either larger than the original rafter chord or connected to it by a continuous gusset plate so that it would effectively create a deeper member.

If the member described above is installed from the wall top plate to the middle of the new horizontal chord, it would become the new bottom chord of a scissor truss. A vertical chord from that point to the ridge would be needed.

A better scissor truss would be to run the new chords from the top plates to the mid-points of the opposite side rafter chords. They could be installed on opposite sides of the the existing rafter chords and blocked together where they cross. The block could be a vertical chord from the intersection to the ridge where it would be attached with a plate or gusset, Similar chords could be installed at the rafter to bottom chord connections down to the other bottom chords. This would basically be a standard Howe Scissors Truss. Nails and or plates are preferred to bolts in such small members.

Unfortunately, the scissor truss might not create as much head room as raising the rafter ties as described above but that could not be determined without more information.

At this point, that's all I can tell you. I hope it's helpful.

Here is a link that might be useful: trusses

mightyanvil

15 years agoYou could sister (adding a member on the side of another) full length 2x8's to each rafter chord, cut the 2x4 bottom chords out and install them as rafter ties half way between the top plates and the ridge. That would create the greatest headroom and allow the new rafters to sit on the top plate in a conventional manner. More wood but less work. Of course, it would have to be checked with the building code for snow loading.

snoonyb

15 years agoWhat I described to you is called a "Raised Tie" Truss.

http://www.acrooftrusses.co.uk/truss/scissor/scissortruss.htmmightyanvil

15 years agoRaising rafter ties/bottom chords a small amount as shown in your example (about 1/6 ridge height), requires making the rafter chords larger for their full length (not what you described) and that makes the framing system part truss and part conventional rafters, a hybrid really.

If the tie were raised another 1/6 the rafters would become large enough to not need any additional chords and would become simple span rafters with rafter ties. In other words, this is not a truss design that could be used to raise the tie to the mid-point of the rafters as you originally suggested.

If all that is desired is a small (1/6 ridge height) increase in headroom, that can be achieved by simply raising the ties as described in the IRC tables and somehow connecting the rafter bottoms to the top plates (not as easy as it sounds).

For greater headroom and a simpler solution to the rafter support problem, the IRC allows a half ridge height 2x4 tie if the rafters are 2x8's (see earlier post).

Alternatively, a scissors truss could be used as I have also described.

A possible variation on the 2x8 rafter/raised-tie solution is to only install them at every other rafter since it could be argued that ties are only needed at 4 ft intervals. (This is true in some codes for collar ties but a building inspector might buy it since the rafter ties are so high and are so poorly described in most codes). Of course, the rafter-to-top plate connection would still have to be modified at the non-reinforced rafters.

I recommend cutting 2x8's to size, sistering them to the existing rafters, nailing them very well to everything they touch (they don't have to touch the sheathing), adding plates and clips as needed, cutting out the old ties (one at a time or several if there's no snow on the roof), nailing them to the new rafters at their mid-points, and be done with it. The wood might be expensive but it will go up fast and it might even pass a code inspection.

2x6 rafters would probably allow a 1/4 height tie but I haven't checked it.

snoonyb

15 years ago"Posted by mightyanvil (My Page) on Fri, Sep 5, 08 at 8:37

Raising rafter ties/bottom chords a small amount as shown in your example (about 1/6 ridge height), requires making the rafter chords larger for their full length (not what you described)"

Sorry!

Again, you don't understand.

You are forgetting that the rafter length at 8:12 pitch(which they clearly are less than), for a 10' span would barely exceed 6',(1/8").The bottom chord would be doubled as would the blocking supporting them, effectively creating a header in conjunction with the added king post.Again! What I described!

Yet you persist in making a mountain out of a mole hill.

mightyanvil

15 years agoThe span and rafter slope are irrelevant.

What you are missing is that a tie raised any distance above a top plate adds a bending moment in the rafter because when the roof is fully loaded, the rafter tie exerts a horizontal force on the rafter which attempts to bend it in the same direction, unfortunately, as the roof live load does.

The main principal of truss design is to reduce the size of structural members by avoiding connections that induce bending moment forces in the members. The higher the tie, the greater the bending moment that is applied to the entire rafter. The truss you show clearly has a larger rafter chord for this reason.

But no amount of blocking or doubling of chords at or below the tie connection could help the rafter resist the bending moment. The entire rafter must be reinforced.

A roof structure should meet either "accepted engineering practice" or comply with the prescriptive residential building code. Your design does neither.

Your design would probably not collapse in a snow storm but there is no reason whatsoever to add blocking, double ties and king posts. The structure would survive only if the existing 2x4 rafters were able to resist the bending moment of the snow plus the additional moment induced by the raised tie and nothing else.

Therefore it is important that the OP understand the limits of his options.

If the clear inside dimension between the studs is 113 inches or less

If there will never be any storage or ceiling above.

If the ground snow load for the area does not exceed 50 psf.

If the roof dead load does not exceed 10 psf.

If the lumber is SPF #2 or better.The existing ties can be raised 18.4% of the current distance between the top plate and the ridge if some way is found to attach the rafter bottoms to the top plates.

The ties can be raisied 50% if 2x6's are sistered to the entire length of the 2x4 rafters and positioned so that they overlap the rafters by half and the top plate by half so they can be effectively nailed.

Let the OP decide what the wants to do. If he thinks we don't know what we're talking about he can hire a professional instead of worrying about the conflicting advice of strangers.

tomslildeere

Original Author15 years agoThanks guys for all your input,I find both sides here useful and entertaining.I have my plan set as to how I will do this now thanks to your advice.I will buy you both a cold brew if you you will make peace! LOL!

mightyanvil

15 years agoIt can sometimes be difficult to understand when a roof structure has changed from a joist system to a rafter & tie system or a truss system.

A simple explanaion is that a rafter & tie system differs from a joist system in that the slope of the rafter and the tension connection of the tie allow the rafter to be sized to resist bending moment, deflection, and shear just like a joist system, but for only half the total span.

A roof truss differs from the two bending moment resisting systems in that it is made up of members that resist tension and compression forces rather than bending moment. An easy test of a truss system is to pretend that all members are free to rotate around the connections regardless of how they are actually going to be built. If the imaginary truss frame can deform when loaded, then you know it will be relying on the bending strength of one or more of the members and that you should treat it to some extent like one of the other systems. It would be unwise to try to design a hybrid system unless you have been trained to do it by hand or with computer software.

snoonyb

15 years agoJust for sh-- and giggles, the last job built truss I worked on spans 63' and supports an overhead crane, is still in operation today in the harbor section of Long Beach CA.

The builder of record had a 4 digit B General Lic. number.Bud Long-neck in a snowbank.

mightyanvil

15 years agoCongratulations to the engineers who designed it. You should call them next time you need to offer advice about a structural issue.

mightyanvil

15 years agoIf you lost the chip on your shoulder you might learn something in this forum.

brickeyee

15 years agoThere are good reasons truss alterations are required to be stamped off by a PE, and many will actually simply refuse if they did not design the truss.

Without ALL the design information it gets time consuming and risky to stamp off alterations.

Trusses often used mixed wood grades depending on the individual member loads.

To even think about stamping off an alteration I would need to verify the grades of each member, re-run all the design calculations, then run them again for the modification.

Trusses a greatly reduce the amount of wood required compared to older framing.

The down side is that the design margins present in older framing methods have been reduced.You will find out if the alteration was performed incorrectly when a wind or snow load causes a failure.

hendricus

15 years agoLooking at your pictures I don't see a truss at all, just ceiling joists. Take out one joist, cut it down and place at the height you want. Repeat for all others.

I've got a 9x12 shed without ceiling joist, just collar ties near the peak.

It's just a shed, not very big and in our area no permit is even needed under 200 sq. ft.

tomslildeere

Original Author15 years agoHendricus, that sounds very simple and i could re-use the same wood.Do you think i would need to reinforce anything else?

mightyanvil

15 years agoTake a closer look at the photos.

The existing structure is, in fact, a very simple truss but only because the rafter chords sit on the ties just beyond the wall plates instead of directly on the plates. If the rafters did rest on the top plates, the ties could simply be raised until the rafters reached their maximum bending capacity (about 6" by the IRC tables with assumptions listed earlier).

Figuring out how to efficiently raise the ties to the mid point of the barely adequate rafters and repair the rafter seat detail has been discussed at length earlier.

I have attempted to give the OP sound structural advice within the parameters I listed because that is what I have been trained to do. If there is no building department oversight and he is willing to tolerate sag in the rafters and movement in the wall top plates during extended snow storms, all he needs to do is block or strap the rafter bottoms to the plates and then raise the ties.

However, all it would take under full loading conditions is for enough tie connections to fail and the shed could collapse. In my opinion, the tie connection overlap is too small for adequate nailing or bolting and should have a metal or wood plate.

Potential structural failure is not an option I would recommend even for a shed.

mightyanvil

15 years agotomslildeer

I think you have enough information to successfully resolve your problem if you have read the comments carefully. If you want additional advice from me, please start a new thread.

Good luck

mightyanvil