Simple carpentry question

pineapplecake

15 years ago

Related Stories

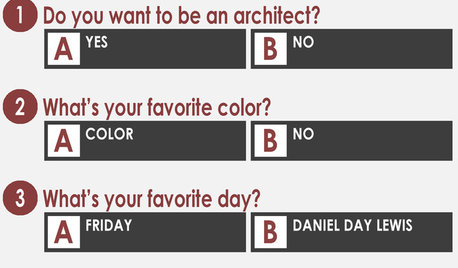

COFFEE WITH AN ARCHITECTA Quiz for Architects in Question

Should you trade in your T-square for a barista tray? Answer a few simple questions to find out

Full Story

ARCHITECTUREThe Truth About 'Simple' Modern Details

They may look less costly and easier to create, but modern reveals, slab doors and more require an exacting hand

Full Story

FEEL-GOOD HOMESimple Pleasures: Make Do and Mend

Experience the satisfaction of fixing, repurposing and creating things yourself around the home

Full Story

FEEL-GOOD HOMEThe Question That Can Make You Love Your Home More

Change your relationship with your house for the better by focusing on the answer to something designers often ask

Full Story

KITCHEN DESIGN9 Questions to Ask When Planning a Kitchen Pantry

Avoid blunders and get the storage space and layout you need by asking these questions before you begin

Full Story

MOST POPULAR8 Questions to Ask Yourself Before Meeting With Your Designer

Thinking in advance about how you use your space will get your first design consultation off to its best start

Full Story

5 Questions for Design Stars

Add Your Ideas for Outdoor Storage, Cheering Up a Fireplace and More

Full Story

WORKING WITH PROS10 Questions to Ask Potential Contractors

Ensure the right fit by interviewing general contractors about topics that go beyond the basics

Full Story

REMODELING GUIDESSurvive Your Home Remodel: 11 Must-Ask Questions

Plan ahead to keep minor hassles from turning into major headaches during an extensive renovation

Full Story

LIGHTING5 Questions to Ask for the Best Room Lighting

Get your overhead, task and accent lighting right for decorative beauty, less eyestrain and a focus exactly where you want

Full Story

Jon1270

bobismyuncle

Related Professionals

Champlin Kitchen & Bathroom Remodelers · Elk Grove Kitchen & Bathroom Remodelers · South Park Township Kitchen & Bathroom Remodelers · Bartlesville General Contractors · Boardman General Contractors · Cumberland General Contractors · Gallatin General Contractors · Norfolk General Contractors · Reisterstown General Contractors · Troy General Contractors · Fort Collins Painters · Genesee Painters · Oak Lawn Painters · Oxford Painters · Ruskin Paintersmike_kaiser_gw

brusso

chester_grant

ci_lantro

rockhead515

davidandkasie

bobismyuncle

davidandkasie

rockhead515

davidandkasie

rockhead515

davidandkasie

rockhead515

User

davidandkasie

mightyanvil

rockhead515

bill_g_web

justnigel

dizzy8

over_n_under

newenglandbuilder