strengthening cut joist

laurarex

12 years ago

Featured Answer

Sort by:Oldest

Comments (29)

renovator8

12 years agolaurarex

12 years agoRelated Professionals

Emeryville Kitchen & Bathroom Remodelers · Hanover Township Kitchen & Bathroom Remodelers · League City Kitchen & Bathroom Remodelers · Southampton Kitchen & Bathroom Remodelers · Plant City Kitchen & Bathroom Remodelers · Four Corners General Contractors · Bound Brook General Contractors · Fitchburg General Contractors · Harvey General Contractors · Kettering General Contractors · Riverdale General Contractors · Fairfield Painters · Weston Painters · South Peabody Painters · Addison Paintersbrickeyee

12 years agolaurarex

12 years agorenovator8

12 years agosdello

12 years agolaurarex

12 years agolaurarex

12 years agolaurarex

12 years agosdello

12 years agobrickeyee

12 years agolaurarex

12 years agobrickeyee

12 years agolaurarex

12 years agobrickeyee

12 years agolaurarex

12 years agolaurarex

12 years agolaurarex

12 years agobrickeyee

12 years agolaurarex

12 years agobrickeyee

12 years agolaurarex

12 years agolaurarex

12 years agobrickeyee

12 years agolaurarex

12 years agobrickeyee

12 years agolaurarex

12 years agobrickeyee

12 years ago

Related Stories

DECORATING GUIDESOn Trend: Cut It Out With Norwegian Seating

You may find these nipped-out chairs extra full of modern style and comfort, thanks to their savvy designs

Full Story

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

COMMUNITY15 Ways to Make Your Neighborhood Better

Does your community lack ... well, a sense of community? Here's how to strengthen that neighborly spirit

Full Story

DECORATING GUIDES13 Stylish Ways to Accent a Bedroom Wall

From tried-and-true favorites to the latest textures, these creative ideas can strengthen your bedroom’s design

Full Story

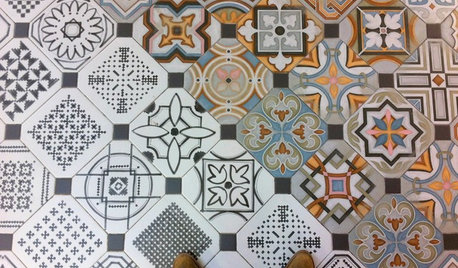

EVENTSTile Goes High Tech at Italy's Big Expo

Cutting-edge methods are creating tile looks from handmade to avant-garde, as seen as CERSAIE 2013

Full Story

KITCHEN DESIGN9 Creative Looks for Kitchen Cabinets

When plain cabinet finishes just won’t cut it, consider these elegant to inventive approaches

Full Story

BEFORE AND AFTERSJumbled Style Goes Vintage Chic in a D.C. Bathroom Makeover

Sloppy on the outside and alarming on the inside, this row house bathroom now sports a clean new look and systems that work

Full Story

SIMPLE PLEASURESThe Art of Being Neighborly

Learn the heartfelt gestures that go a long way toward creating a welcoming community

Full Story

REMODELING GUIDESMaterial Choices: High Marks for Reinforced Concrete

Try poured-in-place construction for a wonderfully tactile, industrial look

Full Story

LANDSCAPE DESIGNConsider a Plant as Living Sculpture

If traditional garden art isn’t really your thing, plant living art instead

Full Story

brickeyee