Drilling Blinds into French Door

roysterfam

13 years ago

Featured Answer

Sort by:Oldest

Comments (18)

User

13 years agobrickeyee

13 years agoroysterfam

13 years agobrickeyee

13 years agowoodbutcher_ca

13 years agoroysterfam

13 years agokudzu9

13 years agomike_kaiser_gw

13 years agoroysterfam

13 years agobrickeyee

13 years agokudzu9

13 years agoroysterfam

13 years agomike_kaiser_gw

13 years agobrickeyee

13 years agoblindambitions1

13 years agobrickeyee

13 years agoroysterfam

13 years ago

Related Stories

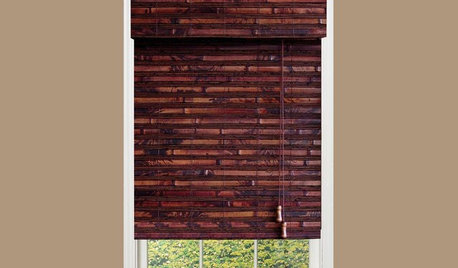

DOORSThe Art of the Window: 12 Ways to Cover Glass Doors

Learn how to use drapes, shutters, screens, shades and more to decorate French doors, sliding doors and Dutch doors

Full Story

VACATION HOMESHouzz Tour: A French Ski Chalet’s Dark Sophistication

A superstylish ski chalet is layered with tactile surfaces, organic textures and warm colors

Full Story

WINDOWSAwkward Windows and Doors? We've Got You Covered

Arched windows, French doors and sidelights get their due with treatments that keep their beauty out in the open

Full Story

FRONT DOOR COLORSFront and Center Color: When to Paint Your Door Bright Red

Welcoming and intense, a red front door kicks up a home's entryway and is impossible to miss

Full Story

FRONT DOOR COLORSFront and Center Color: When to Paint Your Door Blue

Who knew having the blues could be so fun? These 8 exterior color palettes celebrate sunny-day skies to electric nights

Full Story

GREAT HOME PROJECTSUpgrade Your House With New Interior Doors

New project for a new year: Enhance your home's architecture with new interior doors you'll love to live with every day

Full Story

ARCHITECTUREDesign Workshop: The Lowdown on Colossal Doors

Want to erase the boundary to the outdoors? Here’s what to know about materials, cost, energy efficiency and more

Full Story

PRODUCT PICKSGuest Picks: A Whole Lotta Wonderful Window Coverings

Blinds, drapes, shades and curtain rods to give your windows a polished, put-together look

Full Story

MOVING5 Risks in Buying a Short-Sale Home — and How to Handle Them

Don’t let the lure of a great deal blind you to the hidden costs and issues in snagging a short-sale property

Full Story

KITCHEN CABINETS9 Ways to Configure Your Cabinets for Comfort

Make your kitchen cabinets a joy to use with these ideas for depth, height and door style — or no door at all

Full Story

roysterfamOriginal Author