tile saw to cut pavers

stevega

17 years ago

Featured Answer

Sort by:Oldest

Comments (16)

gzec

17 years agoRelated Professionals

Clovis Kitchen & Bathroom Remodelers · Waukegan Kitchen & Bathroom Remodelers · Arlington General Contractors · ‘Ewa Beach General Contractors · Fort Lee General Contractors · New Baltimore General Contractors · River Forest General Contractors · Birmingham Painters · Crest Hill Painters · Cromwell Painters · Emeryville Painters · Kansas City Painters · Lakewood Painters · Shrewsbury Painters · Tustin Paintersbrickeyee

17 years agostevega

17 years agochris8796

17 years agokudzu9

17 years agopjb999

17 years agokudzu9

17 years agostevega

17 years agokudzu9

17 years agostevega

17 years agokudzu9

17 years agostevega

17 years agokudzu9

17 years agostevega

17 years agokudzu9

17 years ago

Related Stories

HOME OFFICESQuiet, Please! How to Cut Noise Pollution at Home

Leaf blowers, trucks or noisy neighbors driving you berserk? These sound-reduction strategies can help you hush things up

Full Story

MATERIALSPrecast Concrete Pavers Make a Versatile Surface in the Garden

You can use concrete pavers in a variety of shapes and colors for your patio, walkway, driveway and more

Full Story

GARDENING AND LANDSCAPINGPatio Pavers Go Green in Between

Kind to the environment and easy on the eyes, pavers with moss or other foliage in the joints create a charming permeable hardscape

Full Story

EVENTSTile Goes High Tech at Italy's Big Expo

Cutting-edge methods are creating tile looks from handmade to avant-garde, as seen as CERSAIE 2013

Full Story

REMODELING GUIDESFinishing Touches: Pro Tricks for Installing Fixtures in Your Tile

Cracked tile, broken drill bits and sloppy-looking fixture installations? Not when you follow these pro tips

Full Story

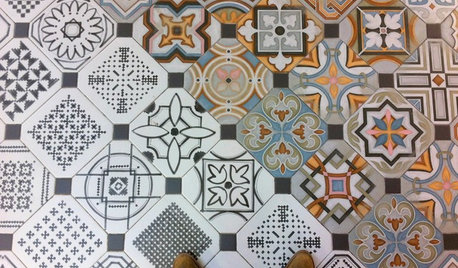

TILEPep Up With Patchwork Tiles

Don't call them crazy — quilt-style tile patterns are bringing energy and playfulness to walls, countertops and even floors

Full Story

REMODELING GUIDESGravel Driveways: Crunching the Pros and Cons

If you want to play rough with your driveway, put away the pavers and choose the rocky road

Full Story

SALVAGECan We Bounce Some Great Recycled-Rubber Ideas Off You?

No need to bemoan that spare tire. Old rubber is getting a guilt-free second life as flooring, pavers, sinks and even furniture

Full Story

KITCHEN BACKSPLASHESHow to Install a Tile Backsplash

If you've got a steady hand, a few easy-to-find supplies and patience, you can install a tile backsplash in a kitchen or bathroom

Full Story

REMODELING GUIDESStraight From Spain: Amazing New Trends in Tile

Innovative Shapes, Patterns, and Textures Take Tile Beyond Kitchen and Bath

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

More Discussions

kudzu9