Can Concrete be Impermeable?

shw001

12 years ago

Related Stories

LANDSCAPE DESIGNWhat the Heck Is a Ha-Ha, and How Can It Help Your Garden?

Take cues from a historical garden feature to create security and borders without compromising a view

Full Story

HOME TECHWhat Chipotle and Radiohead Can Teach Us About Sound Quality at Home

Contemporary designs filled with glass and concrete can be hostile environments for great sound quality. Here's how to fix that

Full Story

REMODELING GUIDESConcrete Driveways: Poring Over the Pros and Cons

Concrete adds smooth polish to driveways and a sleek look to home exteriors, but here are the points to ponder before you re-surface

Full Story

CONTAINER GARDENSYes, You Can Grow a Plant In That

You can upcycle your old typewriter, paint cans, tires and many more things into places for your plants

Full Story

PETS5 Finishes Pets and Kids Can’t Destroy — and 5 to Avoid

Save your sanity and your decorating budget by choosing materials and surfaces that can stand up to abuse

Full Story

COLORWhy Blue and Yellow Can Be Perfect Bedfellows

This color combo evokes clear skies and golden beaches and can bring cheer to even the gloomiest days

Full Story

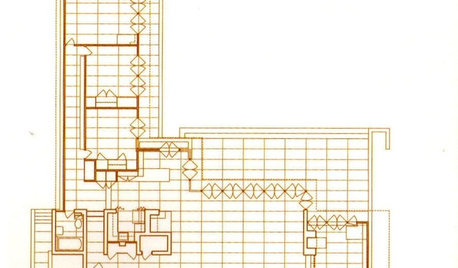

REMODELING GUIDESSee What You Can Learn From a Floor Plan

Floor plans are invaluable in designing a home, but they can leave regular homeowners flummoxed. Here's help

Full Story

COMMUNITYCommunity Building Just About Anyone Can Do

Strengthen neighborhoods and pride of place by setting up more public spaces — even small, temporary ones can make a big difference

Full Story

LAUNDRY ROOMSThe Cure for Houzz Envy: Laundry Room Touches Anyone Can Do

Make fluffing and folding more enjoyable by borrowing these ideas from beautifully designed laundry rooms

Full Story

FLOORS8 Ways Colored Floors Can Boost Your Design

Deep colors add height, white creates calm, and warm hues spark energy. Learn more ways to use floor color to enhance your home

Full Story

sombreuil_mongrel

renovator8

Related Professionals

Frankfort Kitchen & Bathroom Designers · Bay Shore Kitchen & Bathroom Remodelers · Buffalo Grove Kitchen & Bathroom Remodelers · Idaho Falls Kitchen & Bathroom Remodelers · Oxon Hill Kitchen & Bathroom Remodelers · Fairmont Kitchen & Bathroom Remodelers · Clinton Township Interior Designers & Decorators · Clarksville General Contractors · Columbus General Contractors · Leon Valley General Contractors · Medway General Contractors · Rolling Hills Estates General Contractors · Texas City General Contractors · West Melbourne General Contractors · Wheeling General Contractorsbrickeyee

shw001Original Author

hendricus

brickeyee

shw001Original Author

brickeyee

shw001Original Author