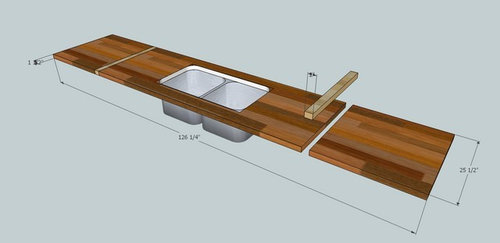

joining sections of butcher block

sardaukar

11 years ago

Featured Answer

Comments (15)

renovator8

11 years agosardaukar

11 years agoRelated Professionals

Normal Kitchen & Bathroom Remodelers · Ewa Beach Kitchen & Bathroom Remodelers · Wilmington Kitchen & Bathroom Remodelers · Tahoe City Interior Designers & Decorators · Salem General Contractors · Auburn General Contractors · Cedar Hill General Contractors · Coatesville General Contractors · Evans General Contractors · Lake Forest Park General Contractors · New River General Contractors · North Tustin General Contractors · Port Washington General Contractors · Westminster General Contractors · Wheaton General ContractorsJumpilotmdm

11 years agohandymac

11 years agobrickeyee

11 years agosardaukar

11 years agobrickeyee

11 years agowi-sailorgirl

11 years agobrickeyee

11 years agokudzu9

11 years agosardaukar

11 years agokudzu9

11 years agonorthcarolina

11 years agosardaukar

11 years ago

Related Stories

KITCHEN DESIGNButcher Block Makes the Cut for Holiday Kitchen Prep

Countertops and cutting boards will likely take a beating over the holidays. These butcher blocks have the chops to perform under pressure

Full Story

WOODWORKINGHow to Clean and Care for Your Butcher Block

Keep butcher block counters and boards looking sharp as a knife — and sanitized for safe food prep — with this advice from a pro woodworker

Full Story

FURNITUREWhat to Know Before You Buy a Sectional

Learn about sizes, arm setups, seat types and more to get the right sectional for your space

Full Story

TINY HOUSESAdventure Seekers Hit the Road in a Cozy School Bus Home

Wood floors, butcher block countertops, custom furnishings and LED lights make life on the road feel like just another stylish day at home

Full Story

HOUZZ TVHouzz TV: A Famed ‘Painted Lady’ Gets a Gorgeous Update

Join us as we walk with the homeowners through one of San Francisco's landmark Victorians, lovingly restored

Full Story

VINTAGE STYLEKitchen of the Week: Preservation Instincts Create Vintage Modern Style

Original features in this 1908 kitchen join new custom accents for a look that bridges the years

Full Story

HOUZZ TOURSMy Houzz: Vintage Flair for a Lovingly Maintained Midcentury Gem

Antiques join luxe textiles and rich wallpapers to give a Dallas home by Ju-Nel sophistication and warmth

Full Story

THE ART OF ARCHITECTUREToys to Inspire Budding Architects and Designers

Frank Lloyd Wright’s blocks, cards by Eames and more toys from around the globe tap into kids’ imaginations and build skills

Full Story

HOUZZ CALLShow Us the Best Kitchen in the Land

The Hardworking Home: We want to see why the kitchen is the heart of the home

Full Story

writersblock (9b/10a)