Am I crazy to set 'moisture content' of framing in specs?

la_koala

12 years ago

Related Stories

URBAN GARDENSA Dynamic Backyard Design Embraces Its Urban Setting

A New York City outdoor space comes to life with a curvy new brick patio, thoughtful outdoor furnishings and evergreen foliage

Full Story

PRODUCT PICKSGuest Picks: Make a Meaningful Display Wall

Personalize your walls to your heart's content with shelves, clips, frames and customizable art

Full Story

WINDOWSSteel-Framed Windows Leap Forward Into Modern Designs

With a mild-mannered profile but super strength, steel-framed windows are champions of design freedom

Full Story

DECORATING GUIDESThe Dumbest Decorating Decisions I’ve Ever Made

Caution: Do not try these at home

Full Story

LIFEThe Polite House: How Can I Kindly Get Party Guests to Use Coasters?

Here’s how to handle the age-old entertaining conundrum to protect your furniture — and friendships

Full Story

REMODELING GUIDESTop 10 Tips for Choosing Shower Tile

Slip resistance, curves and even the mineral content of your water all affect which tile is best for your shower

Full Story

WHITE KITCHENSKitchen of the Week: Splashes of Color and Country Charm

An all-white spec-house kitchen in Los Angeles goes a little bit country and gets a whole lot of fun

Full Story

KITCHEN CABINETSCabinets 101: How to Choose Construction, Materials and Style

Do you want custom, semicustom or stock cabinets? Frameless or framed construction? We review the options

Full Story

TASTEMAKERSTake a Behind-the-Scenes Tour of Netflix’s ‘Grace and Frankie’

Set decorator Beauchamp Fontaine explains the design decisions behind the home sets featured in the new Netflix series

Full Story

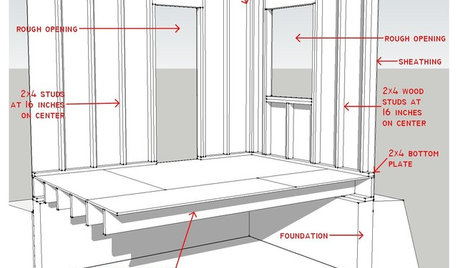

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full StorySponsored

Columbus Area's Luxury Design Build Firm | 17x Best of Houzz Winner!

More Discussions

renovator8

la_koalaOriginal Author

Related Professionals

Brownsville Kitchen & Bathroom Designers · Flint Kitchen & Bathroom Designers · Owasso Kitchen & Bathroom Designers · Sun City Kitchen & Bathroom Designers · Clovis Kitchen & Bathroom Remodelers · Oceanside Kitchen & Bathroom Remodelers · South Park Township Kitchen & Bathroom Remodelers · Spanish Springs Kitchen & Bathroom Remodelers · Enumclaw General Contractors · Jackson General Contractors · Ken Caryl General Contractors · Los Alamitos General Contractors · Milford Mill General Contractors · North New Hyde Park General Contractors · Oxon Hill General Contractorsrenovator8

la_koalaOriginal Author

renovator8

User

renovator8

renovator8

renovator8

brickeyee

renovator8

brickeyee

MongoCT

la_koalaOriginal Author