Need Brother's Machine HELP....

wynative

12 years ago

Related Stories

TASTEMAKERSBask in the 'Microarchitecture' of the Innovative Bouroullec Brothers

Provocative and original wall, furniture and lighting designs on display in Chicago make the user central to the experience

Full Story

VINTAGE STYLEAntique Sewing Machines: Tailor Made for Nostalgic Decor

In full-on vintage rooms or contrasting modern looks, old sewing machines and tables are stirring up the past in a most stylish way

Full Story

LIFEDecluttering — How to Get the Help You Need

Don't worry if you can't shed stuff and organize alone; help is at your disposal

Full Story

DECLUTTERINGDownsizing Help: How to Get Rid of Your Extra Stuff

Sell, consign, donate? We walk you through the options so you can sail through scaling down

Full Story

REMODELING GUIDES8 Tips to Help You Live in Harmony With Your Neighbors

Privacy and space can be hard to find in urban areas, but these ideas can make a difference

Full Story

ORGANIZING6 Ways to Care for Your Washing Machine

Keep your laundry room and clothes in great shape with these basic washing machine tips

Full Story

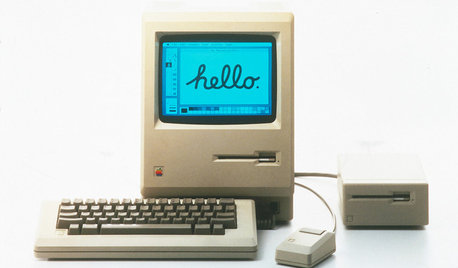

HOME TECHTurn 'Obsolete' Tech Into Fun Home Help

Here's how to put your old Mac, Atari or Newton to work around the house

Full Story

SELLING YOUR HOUSE10 Low-Cost Tweaks to Help Your Home Sell

Put these inexpensive but invaluable fixes on your to-do list before you put your home on the market

Full Story

ORGANIZINGDo It for the Kids! A Few Routines Help a Home Run More Smoothly

Not a Naturally Organized person? These tips can help you tackle the onslaught of papers, meals, laundry — and even help you find your keys

Full Story

HOUSEKEEPINGThree More Magic Words to Help the Housekeeping Get Done

As a follow-up to "How about now?" these three words can help you check more chores off your list

Full StorySponsored

More Discussions

sunnycentralfl

magothyrivergirl

Related Professionals

Mansfield Furniture & Accessories · Portland Furniture & Accessories · Newton Furniture & Accessories · Annandale Furniture & Accessories · North Hollywood Furniture & Accessories · Eastvale Flooring Contractors · Greenville Flooring Contractors · Napa Flooring Contractors · South Lake Tahoe Flooring Contractors · Washington Flooring Contractors · North Bergen Furniture & Accessories · Savannah Furniture & Accessories · North Hollywood Furniture & Accessories · Rogers Furniture & Accessories · Wakefield Furniture & AccessoriesK8Orlando

msmeow

day2day

wynativeOriginal Author

Robbi D.

magothyrivergirl

wynativeOriginal Author

magothyrivergirl