Fencing

nnlogistics

12 years ago

Related Stories

FENCES AND GATESHow to Choose the Right Fence

Get the privacy, security and animal safeguards you need with this guide to fencing options

Full Story

FENCES AND GATESA Deer Fence Can Be Decorative as Well as Protective

You need a monster-size fence to shelter your garden from deer, but it doesn’t have to look like a monstrosity

Full Story

FENCES AND GATESHow to Install a Wood Fence

Gain privacy and separate areas with one of the most economical fencing choices: stained, painted or untreated wood

Full Story

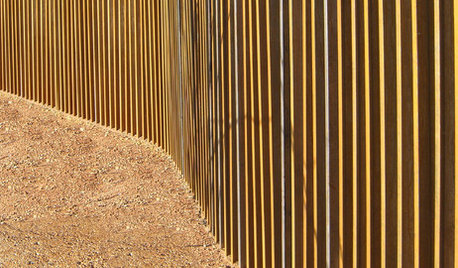

LANDSCAPE DESIGNGood Fences, Good Neighbors — and Good Views

See-through vertical fencing connects a yard with its surroundings while keeping children and pets safely inside

Full Story

LANDSCAPE DESIGNHow to Choose a Fence That Feels Right and Works Hard

Making a thoughtful fencing choice now can create happiness for years to come

Full Story

FENCES AND GATES12 Delightfully Different Garden Walls and Fences

If pickets seem picked over and you shrink from chain link, try these full-of-personality fencing alternatives

Full Story

FENCES AND GATESModern Fencing for a More Secure Home

Deter would-be burglars without robbing your home of style, by installing a modern fence like one of these

Full Story

CURB APPEAL7 Questions to Help You Pick the Right Front-Yard Fence

Get over the hurdle of choosing a fence design by considering your needs, your home’s architecture and more

Full Story

EXTERIORS11 Fences to Match a Modern Mood

Pass on the picket — steel, glass and other materials let fences make a perfect union with modern house mates

Full Story

LANDSCAPE DESIGN10 Creative Fence Designs

Unique materials and imaginative applications turn this yard staple into a powerful outdoor accessory

Full StoryMore Discussions

fnmroberts

sierraeast

Related Professionals

Minneapolis Decks, Patios & Outdoor Enclosures · Prichard Decks, Patios & Outdoor Enclosures · Verona Decks, Patios & Outdoor Enclosures · Valencia Home Builders · Cedar Rapids Flooring Contractors · Conyers Flooring Contractors · Englewood Flooring Contractors · Pahrump Flooring Contractors · Tewksbury Flooring Contractors · Truckee Flooring Contractors · Bronx Siding & Exteriors · Broomfield Siding & Exteriors · Cypress Siding & Exteriors · Oak Forest Siding & Exteriors · North Highlands Siding & Exteriorstexfoolette

MongoCT

sierraeast

MongoCT

sierraeast

nnlogisticsOriginal Author

MongoCT