How to Attach Ledger to Concrete Wall?

java_man

17 years ago

Related Stories

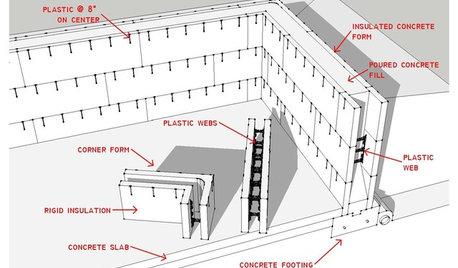

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

INDUSTRIAL STYLERoom of the Day: Concrete Block Goes Chic in a Living Room

Designers put a fresh face on a workaday material in this Washington, D.C., condo

Full Story

KITCHEN COUNTERTOPSKitchen Counters: Concrete, the Nearly Indestructible Option

Infinitely customizable and with an amazingly long life span, concrete countertops are an excellent option for any kitchen

Full Story

MATERIALS10 Cool Things to Do With Concrete in Your House

Humble concrete is being reinvented in everything from bathroom fixtures to lampshades

Full Story

GREEN BUILDINGHouzz Tour: See a Concrete House With a $0 Energy Bill

Passive House principles and universal design elements result in a home that’ll work efficiently for the long haul

Full Story

FLOORS5 Benefits to Concrete Floors for Everyday Living

Get low-maintenance home flooring that creates high impact and works with home styles from traditional to modern

Full Story

LANDSCAPE DESIGNGarden Walls: Gabion Evolves From Functional to Fabulous

The permeable rock-, concrete- or glass-filled steel cages are showing up as retaining walls, planters, benches and more

Full Story

GARDENING AND LANDSCAPING6 Ways to Rethink Your Patio Floor

Figure out the right material for your spring patio makeover with this mini guide to concrete, wood, brick and stone

Full Story

MATERIALSRaw Materials Revealed: Brick, Block and Stone Help Homes Last

Learn about durable masonry essentials for houses and landscapes, and why some weighty-looking pieces are lighter than they look

Full Story

GARDENING AND LANDSCAPINGHow to Pick a Nice Wall for Your Garden Room

Made by hand, prefab or growing from the ground, garden walls are key landscaping elements. Here's what to think about for your yard

Full Story

brickeyee

john_hyatt

Related Professionals

Atlantic City Decks, Patios & Outdoor Enclosures · Jeffersonville Decks, Patios & Outdoor Enclosures · Oswego Decks, Patios & Outdoor Enclosures · Harrisburg Home Builders · Salisbury Home Builders · Beaumont Flooring Contractors · Leland Flooring Contractors · Riverhead Flooring Contractors · Severna Park Flooring Contractors · Westlake Flooring Contractors · Winchester Flooring Contractors · Cocoa Flooring Contractors · Columbus Siding & Exteriors · Richmond Siding & Exteriors · Worcester Siding & Exteriorsjava_manOriginal Author

brooklyndecks

srercrcr

brickeyee

brooklyndecks

brickeyee

brickeyee

srercrcr

john_hyatt

brickeyee

srercrcr

brickeyee

brooklyndecks

srercrcr

irishbrewer

irishbrewer

srercrcr

brickeyee

irishbrewer

derekjoel_gmail_com

Melm813_yahoo_com