Ipe deck Colorado New build questions

Difiore

12 years ago

Related Stories

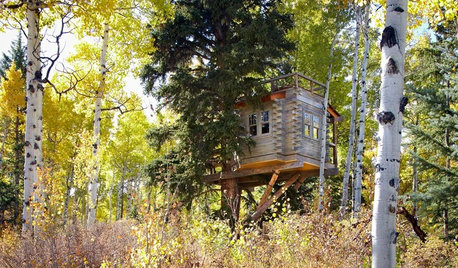

TREE HOUSESSwaying From Sleepovers to Dinner Parties in a Colorado Tree House

Folks of all ages have it made in the shade in this fun little house, thanks to electricity, a kitchenette and a rooftop deck

Full Story

HOUZZ TOURSHouzz Tour: A Straw-Bale Getaway With Sweeping Views

Using passive solar and other green building methods, this Colorado home creates an energy-conscious vacation spot for a family of 5

Full Story

MOST POPULARWhat to Know About Adding a Deck

Want to increase your living space outside? Learn the requirements, costs and other considerations for building a deck

Full Story

CONTRACTOR TIPSBuilding Permits: The Submittal Process

In part 2 of our series examining the building permit process, learn what to do and expect as you seek approval for your project

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

FARM YOUR YARDHow to Build a Raised Bed for Your Veggies and Plants

Whether you’re farming your parking strip or beautifying your backyard, a planting box you make yourself can come in mighty handy

Full Story

GREEN BUILDINGHow to Start Finding a Greener House

On the hunt for a more ecofriendly house? Here are the questions to ask and research to do

Full Story

GARDENING AND LANDSCAPINGChoosing a Deck: Plastic or Wood?

Get the pros and cons of wood, plastic, composite and more decking materials, plus a basic price comparison

Full Story

GARDENING AND LANDSCAPINGBook to Know: 'Deck Ideas That Work'

Considering a new deck? Peter Jeswald's handy volume offers loads of design and material ideas

Full Story

REMODELING GUIDESRegional Modern: Austin, Texas

Contemporary and modern Austin homes reflect the area's climate and eclectic style

Full Story

salmon_slayer

brooklyndecks

DifioreOriginal Author

dooer

john_hyatt

DifioreOriginal Author

john_hyatt

dooer

DifioreOriginal Author

valgal99

DifioreOriginal Author

brooklyndecks

DifioreOriginal Author

john_hyatt

sfmomoxo

john_hyatt