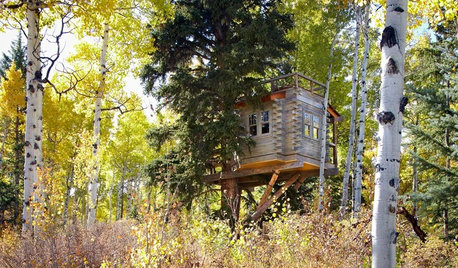

hardwood deck project in colorado

eclaessens

13 years ago

Related Stories

REMODELING GUIDESProject Tour: New Urbanism in Colorado

High-density community forges its own style from a mix of influences, uses and sustainable design ideas

Full Story

TREE HOUSESSwaying From Sleepovers to Dinner Parties in a Colorado Tree House

Folks of all ages have it made in the shade in this fun little house, thanks to electricity, a kitchenette and a rooftop deck

Full Story

HOUZZ TOURSMy Houzz: German Prefab Home in the Colorado Mountains

This modern house was ordered from a website, but its clean-lined, elegant design belies its prefab origins

Full Story

FLOORSHow to Paint Your Hardwood Floors

Know how to apply nail polish? Then you can give your wooden floors a brand-new look

Full Story

MATERIALSWhat to Ask Before Choosing a Hardwood Floor

We give you the details on cost, installation, wood varieties and more to help you pick the right hardwood flooring

Full Story

GARDENING AND LANDSCAPING8 Rot-Resistant Woods for Your Outdoor Projects

No need for chemical treatments on your deck or pergola. These woods stand up to weather, insects and time beautifully on their own

Full Story

DECKSDecking Materials Beyond Basic Lumber

Learn about softwoods, tropical hardwoods, composites and more for decks, including pros, cons and costs

Full Story

MOST POPULARWhat to Know About Adding a Deck

Want to increase your living space outside? Learn the requirements, costs and other considerations for building a deck

Full Story

REMODELING GUIDESContractor Tips: Smooth Moves for Hardwood Floors

Dreaming of gorgeous, natural wood floors? Consider these professional pointers before you lay the first plank

Full Story

PAINTING10 Rules for Your Next Painting Project

Take your next painting journey from ‘argh!’ to ‘ta-da!’ with these designer tricks

Full StoryMore Discussions

john_hyatt

eclaessensOriginal Author

Related Professionals

Baker Decks, Patios & Outdoor Enclosures · Carmel Decks, Patios & Outdoor Enclosures · Conroe Decks, Patios & Outdoor Enclosures · Pittsburgh Decks, Patios & Outdoor Enclosures · Woodstock Decks, Patios & Outdoor Enclosures · Bellview Home Builders · Chula Vista Home Builders · Fresno Home Builders · Westwood Home Builders · Kearns Home Builders · Kent Flooring Contractors · Laguna Beach Flooring Contractors · Lawndale Flooring Contractors · Stoughton Flooring Contractors · Wilmington Siding & Exteriorsbrooklyndecks

weedyacres

john_hyatt

eclaessensOriginal Author

eclaessensOriginal Author

MongoCT