Pergola Beam Span 18'

bemis

16 years ago

Featured Answer

Comments (47)

theporchguy

16 years agodeckman22

16 years agoRelated Professionals

Solana Beach Decks, Patios & Outdoor Enclosures · Commerce City Decks, Patios & Outdoor Enclosures · Lancaster Decks, Patios & Outdoor Enclosures · Lewisville Decks, Patios & Outdoor Enclosures · Markham Decks, Patios & Outdoor Enclosures · Pittsburgh Decks, Patios & Outdoor Enclosures · University Park Home Builders · South Hill Home Builders · Anaheim Flooring Contractors · Gretna Flooring Contractors · Hugo Flooring Contractors · Lewis Center Flooring Contractors · Washougal Flooring Contractors · Rosemont Siding & Exteriors · Cedar Park Siding & Exteriorstheporchguy

16 years agobemis

16 years agobuiltbymac

16 years agodooer

16 years agochuckr

16 years agojohn_hyatt

16 years agobemis

16 years agojohn_hyatt

16 years agobemis

16 years agojohn_hyatt

16 years agodecker173

16 years agobemis

16 years agojohn_hyatt

16 years agoscvinyl

15 years agocsmith1

15 years agodeckman22

15 years agobemis

15 years agodeckman22

15 years agopharaoh

13 years agov1rt

13 years agobemis

13 years agov1rt

13 years agobemis

13 years agosean_kirbyhome_net

13 years agobemis

13 years agosean_kirbyhome_net

12 years agobemis

12 years agosean_kirbyhome_net

12 years agosean_kirbyhome_net

12 years agobemis

12 years agoflleal_sbcglobal_net

12 years agobemis

12 years agothe4rights

11 years agomillworkman

11 years agothe4rights

11 years agoweb037

11 years agothe4rights

11 years agoweb037

11 years agobemis

11 years agothe4rights

11 years agoweb037

11 years agojawahar05pr

7 years agojawahar05pr

7 years agoRugged Dug

2 years ago

Related Stories

HOUZZ TOURSMy Houzz: An 18th-Century Cottage on a Tiny English Island

Once a place for a miller to store his cart, this tiny building is now a cozy home, redesigned using reclaimed materials

Full Story

MY HOUZZMy Houzz: Past and Present Harmonize in an 18th-Century Maine Home

Treasures from the past, contemporary colors and a drum set just like Ringo Starr's warm up this chef’s home

Full Story

PATIOSPatio Details: Hamptons Patio Invites Visitors to Unwind

A pergola made from western red cedar shelters visitors poolside at this New York retreat

Full Story

GARDENING AND LANDSCAPINGPatio Details: Sliding Fabric Panels Filter the Light Just Right

Stepping up to the harsh sun and heat of the desert Southwest, this intimate patio is an exotic escape right outside

Full Story

GARDENING AND LANDSCAPING8 Rot-Resistant Woods for Your Outdoor Projects

No need for chemical treatments on your deck or pergola. These woods stand up to weather, insects and time beautifully on their own

Full Story

GARDENING AND LANDSCAPINGContractor Tips: Build a Top-Notch Deck

Get an outdoor deck that fits your lifestyle and stands the test of time by keeping these 4 considerations in mind

Full Story

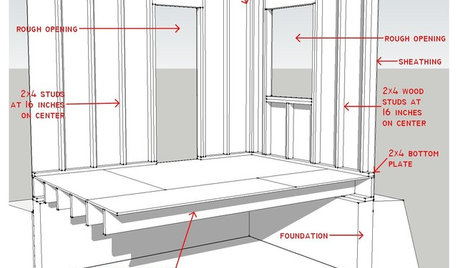

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

KITCHEN DESIGNKitchen of the Week: Resurrecting History on a New York Farm

Built with a 1790 barn frame, this modern-rustic kitchen on a working farm honors the past and makes connections in the present

Full Story

KITCHEN DESIGNTrending Now: 25 Kitchen Photos Houzzers Can’t Get Enough Of

Use the kitchens that have been added to the most ideabooks in the last few months to inspire your dream project

Full Story

MOST POPULARThe 25 Most Popular Photos Added to Houzz in 2013

See the newly uploaded images of kitchens, bathrooms, bedrooms and more that Houzz users really fell for this year

Full Story

bemisOriginal Author