Out with old, pictures are working!

heretoplease

15 years ago

Related Stories

TRADITIONAL ARCHITECTUREHouzz Tour: Taking ‘Ye Olde’ Out of a Nantucket Shingle-Style Home

Vintage and modern pieces mix it up in a vacation house reconfigured to host casual gatherings of family and friends

Full Story

KITCHEN DESIGNBreaking Out of the Kitchen Work Triangle

Keep the efficiency but lose the rigidity with kitchen designs that don't box you in

Full Story

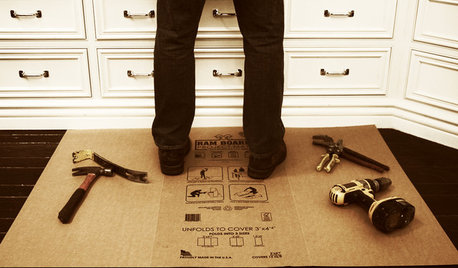

BATHROOM DESIGNOut With the Old Tile: 8 Steps to Prep for Demolition

This isn't a light DIY project: You'll need heavy-duty tools and plenty of protection for your home and yourself

Full Story

UNIVERSAL DESIGNMy Houzz: Universal Design Helps an 8-Year-Old Feel at Home

An innovative sensory room, wide doors and hallways, and other thoughtful design moves make this Canadian home work for the whole family

Full Story

VINTAGE STYLEDial Into Old Phones for Decor With Character

Give a nostalgic nod to the past with vintage telephones, working or not. Booths and sawdust optional.

Full Story

GARDENING AND LANDSCAPINGOld-School Green Design: Art Imitates Plants

Enjoy the play of color and form when nature and design work together

Full Story

DECORATING PROJECTSWhat to Do With Old Family Photos

Find out how to research, share and preserve images that offer a connection to the past

Full Story

HOUZZ TVHouzz TV: See a Funky Beach Home Made From Old Streetcars

A bold color palette zaps life into a Santa Cruz, California, home built out of two streetcars from the early 1920s

Full Story

DECORATING GUIDESUse It or Lose It: How to Get Rid of Old Keys

Clean out your junk drawer by getting rid of keys in an earth-friendly way

Full Story

WORKING WITH PROSWorking With Pros: When You Just Need a Little Design Guidance

Save money with a design consultation for the big picture or specific details

Full StoryMore Discussions

poolguynj

heretopleaseOriginal Author

Related Professionals

Buena Park Swimming Pool Builders · Manassas Swimming Pool Builders · Bridgeview Landscape Contractors · Long Branch Landscape Contractors · Mastic Beach Landscape Contractors · Milford Landscape Contractors · Mission Bend Landscape Contractors · Saint George Landscape Contractors · View Park-Windsor Hills Landscape Contractors · Clermont Decks, Patios & Outdoor Enclosures · Houston Decks, Patios & Outdoor Enclosures · Lenexa Decks, Patios & Outdoor Enclosures · Puyallup Decks, Patios & Outdoor Enclosures · Rogers Decks, Patios & Outdoor Enclosures · Salt Lake City Decks, Patios & Outdoor Enclosurespoolguynj

heretopleaseOriginal Author

poolguynj