pvc v abs v cast iron for dwv

kirkhall

11 years ago

Featured Answer

Comments (6)

geller

11 years agolast modified: 9 years agoRelated Professionals

Harmony Plumbers · Cloverly Kitchen & Bathroom Remodelers · Albuquerque Kitchen & Bathroom Remodelers · Athens Kitchen & Bathroom Remodelers · Chester Kitchen & Bathroom Remodelers · Elk Grove Village Kitchen & Bathroom Remodelers · Eureka Kitchen & Bathroom Remodelers · Glen Carbon Kitchen & Bathroom Remodelers · Lisle Kitchen & Bathroom Remodelers · Omaha Kitchen & Bathroom Remodelers · Saint Helens Kitchen & Bathroom Remodelers · Sicklerville Kitchen & Bathroom Remodelers · York Kitchen & Bathroom Remodelers · Middlesex Kitchen & Bathroom Remodelers · South Jordan Kitchen & Bathroom Remodelerstjdabomb

11 years agolast modified: 9 years agokirkhall

11 years agolast modified: 9 years agotjdabomb

11 years agolast modified: 9 years agokirkhall

11 years agolast modified: 9 years ago

Related Stories

LIFEHow Your Landscaping Can Keep Burglars Away

Prevent home break-ins with strategic landscaping and good practices instead of menacing — and maybe less effective — measures

Full Story

MATERIALSAre You a Maker? Show Us Your Favorite Tool or Material

Houzz Call: A tool or material can be a maker’s best friend. We’d like to see your favorite — and what it helps you achieve

Full Story

GREEN BUILDINGWhy You Might Want to Build a House of Straw

Straw bales are cheap, easy to find and DIY-friendly. Get the basics on building with this renewable, ecofriendly material

Full Story

KITCHEN DESIGNThe 100-Square-Foot Kitchen: Farm Style With More Storage and Counters

See how a smart layout, smaller refrigerator and recessed storage maximize this tight space

Full Story

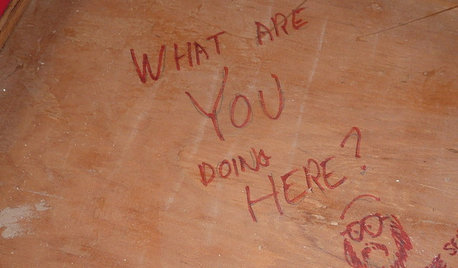

FUN HOUZZDoes Your Home Have a Hidden Message?

If you have ever left or found a message during a construction project, we want to see it!

Full Story

GREEN BUILDINGHow to Harvest Rainwater for Your Garden

Conserve a vital resource and save money by collecting stormwater for irrigation in a barrel or tank

Full Story

GARDENING AND LANDSCAPINGHouzz Call: Show Us Your Great Patio, Deck or Rooftop!

Give your patio a chance at the spotlight as we head outdoors for a new summer ideabook series

Full StoryMore Discussions

lazypup