Shower plumbing in exterior walls?

davmp

14 years ago

Featured Answer

Sort by:Oldest

Comments (18)

rogerv_gw

14 years agolast modified: 9 years agoalphonse

14 years agolast modified: 9 years agoRelated Professionals

Grain Valley Kitchen & Bathroom Remodelers · Holden Kitchen & Bathroom Remodelers · Wood River Kitchen & Bathroom Remodelers · Biloxi Kitchen & Bathroom Remodelers · Ewa Beach Kitchen & Bathroom Remodelers · Hanover Township Kitchen & Bathroom Remodelers · Kendale Lakes Kitchen & Bathroom Remodelers · Mooresville Kitchen & Bathroom Remodelers · Ogden Kitchen & Bathroom Remodelers · Panama City Kitchen & Bathroom Remodelers · Pinellas Park Kitchen & Bathroom Remodelers · South Park Township Kitchen & Bathroom Remodelers · Upper Saint Clair Kitchen & Bathroom Remodelers · Warren Kitchen & Bathroom Remodelers · Tanque Verde Kitchen & Bath Fixtureslazypup

14 years agolast modified: 9 years agojake2007

14 years agolast modified: 9 years agodavmp

14 years agolast modified: 9 years agoalphonse

14 years agolast modified: 9 years agobrickeyee

14 years agolast modified: 9 years agoalphonse

14 years agolast modified: 9 years agobrickeyee

14 years agolast modified: 9 years agoalphonse

14 years agolast modified: 9 years agokudzu9

14 years agolast modified: 9 years agolazypup

14 years agolast modified: 9 years agodavmp

14 years agolast modified: 9 years agojake2007

14 years agolast modified: 9 years agodavmp

14 years agolast modified: 9 years agoInbethlehem

10 years agolast modified: 9 years agokudzu9

10 years agolast modified: 9 years ago

Related Stories

REMODELING GUIDESUmbrella House Creates Shower of Inspiration

The forecast is shade, reduced cooling costs and striking visuals for houses with canopies inspired by a 1950s icon

Full Story

BATHROOM DESIGNDesigner Trick: Take Your Shower Tile to the Ceiling

Tile the whole wall in your shower to give your bath a light and lofty feel

Full Story

HOUSEKEEPINGHow to Clean a Glass Shower Door

See which tools and methods will keep those glass shower walls and doors sparkling clean

Full Story

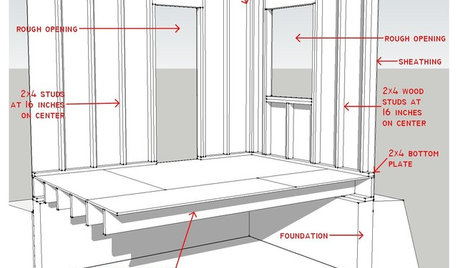

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

GARDENING AND LANDSCAPING14 Design Ideas for an Exhilarating Outdoor Shower

Enhance an open-air shower with amenities and style upgrades from the all-essential towel hook to total landscape integration

Full Story

REMODELING GUIDESTop 10 Tips for Choosing Shower Tile

Slip resistance, curves and even the mineral content of your water all affect which tile is best for your shower

Full Story

BATHROOM DESIGNDream Spaces: Spa-Worthy Showers to Refresh the Senses

In these fantasy baths, open designs let in natural light and views, and intriguing materials create drama

Full Story

SHOWERSTurn Your Shower Niche Into a Design Star

Clear glass surrounds have raised the design bar for details such as shampoo and soap shelves. Here are 4 standouts

Full Story

SHOWERSYour Guide to Shower Floor Materials

Discover the pros and cons of marble, travertine, porcelain and more

Full Story

BATHROOM DESIGNConvert Your Tub Space to a Shower — the Fixtures-Shopping Phase

Step 2 in swapping your tub for a sleek new shower: Determine your mechanical needs and buy quality fixtures

Full Story

lazypup