Need help with Pressure Regulator (see picture)

thomas_e

11 years ago

Related Stories

PETSSee a Deluxe 'Catio' Built for Feline Fun

Sixteen lucky cats get the run of a protected outdoor patio with ramps, steps and even a koi pond

Full Story

BATHROOM WORKBOOKStandard Fixture Dimensions and Measurements for a Primary Bath

Create a luxe bathroom that functions well with these key measurements and layout tips

Full Story

STANDARD MEASUREMENTSThe Right Dimensions for Your Porch

Depth, width, proportion and detailing all contribute to the comfort and functionality of this transitional space

Full Story

REMODELING GUIDESCoastal Makeover: A Florida Home Sees the Light

They're done! Check out the result of a ranch home that went from dark and dated to bright and airy — with a coveted water view

Full Story

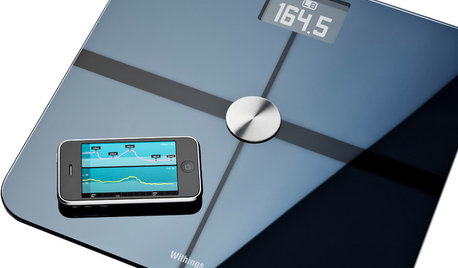

HOME TECHGadgets Help You Watch Your Health at Home

See the crop of new devices that can monitor your body's vital signs and environment for health, fitness and fun

Full Story

HOUZZ TOURSHouzz TV: See a Modern Family Farmhouse That Can Pick Up and Move

In the latest episode of Houzz TV, watch California architect build a beautifully practical cabin to jumpstart his parents' new farm

Full Story

FLOORSHow to Get a Tile Floor Installed

Inventive options and durability make tile a good choice for floors. Here’s what to expect

Full Story

BEFORE AND AFTERSHouzz TV: See Recycled Walls and Cool Cassette Art in a Woodsy DIY Home

Walnut countertops join hardwood floors and pieces made from leftover framing in a bright Spanish colonial

Full Story

BEFORE AND AFTERSSee 6 Yards Transformed by Losing Their Lawns

Wondering whether a turf lawn is the best use of your outdoor space? These homeowners did, and they found creative alternatives

Full Story

EXTERIORSHelp! What Color Should I Paint My House Exterior?

Real homeowners get real help in choosing paint palettes. Bonus: 3 tips for everyone on picking exterior colors

Full StoryMore Discussions

lazypup

thomas_eOriginal Author

Related Professionals

Andover Kitchen & Bathroom Remodelers · Blasdell Kitchen & Bathroom Remodelers · Buffalo Grove Kitchen & Bathroom Remodelers · Dearborn Kitchen & Bathroom Remodelers · Mesquite Kitchen & Bathroom Remodelers · Payson Kitchen & Bathroom Remodelers · Tempe Kitchen & Bathroom Remodelers · Vancouver Kitchen & Bathroom Remodelers · Vashon Kitchen & Bathroom Remodelers · Vista Kitchen & Bathroom Remodelers · Shaker Heights Kitchen & Bathroom Remodelers · North Chicago Kitchen & Bathroom Remodelers · Glenn Heights Kitchen & Bathroom Remodelers · Ridgefield Park Kitchen & Bathroom Remodelers · Kiryas Joel Applianceslazypup

thomas_eOriginal Author

thomas_eOriginal Author

thomas_eOriginal Author

thomas_eOriginal Author

thomas_eOriginal Author

woodbutcher_ca