How to transition from cast iron to ABS pics

orourke

14 years ago

Related Stories

KITCHEN DESIGNKitchen Sinks: Enameled Cast Iron for Attractive Durability

Strong, shiny and sustainable, an enameled cast iron sink can bring character to your kitchen

Full Story

REMODELING GUIDESOriginal Home Details: What to Keep, What to Cast Off

Renovate an older home without regrets with this insight on the details worth preserving

Full Story

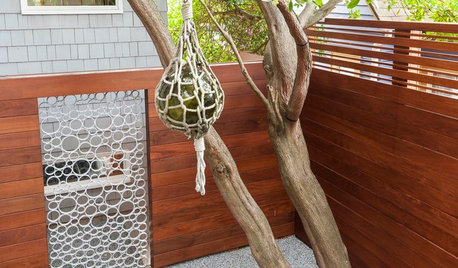

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

GARDENING AND LANDSCAPINGSee a Soothing Backyard Bathhouse Born From a Salvaged Tub

Creative thinking and DIY skills give a Portland couple a pergola-covered 'hot tub' under the stars

Full Story

VINTAGE STYLEGet Away From It All in a Glamper

A glammed-up camper can transport you to a happy place, whether in your yard or on the highway

Full Story

DECORATING GUIDES6 Lessons in Scale From Well-Designed Bathrooms

See how to mix shapes and sizes for an interesting and balanced bathroom design

Full Story

TRADITIONAL HOMESHouzz Tour: Historic Coastal Home Is Rescued From Neglect

A designer lavishes TLC on a splendid Normandy revival house in Laguna Beach, embracing its original style in the renovation

Full Story

DECORATING GUIDESHouzz Tour: Traditional Meets Transitional in a Townhouse

A Southern California couple downsizes, and their designer helps them push past traditional boundaries

Full Story

REMODELING GUIDESSliding Doors: Transition in High Style

Clever Sliding Doors Save Space, Hide Clutter and Amp Up Your Design

Full Story

lazypup

hendricus

Related Professionals

Franklin Plumbers · East Tulare County Kitchen & Bathroom Remodelers · Apex Kitchen & Bathroom Remodelers · Camarillo Kitchen & Bathroom Remodelers · Crestline Kitchen & Bathroom Remodelers · Creve Coeur Kitchen & Bathroom Remodelers · Ewa Beach Kitchen & Bathroom Remodelers · Kendale Lakes Kitchen & Bathroom Remodelers · Lincoln Kitchen & Bathroom Remodelers · Los Alamitos Kitchen & Bathroom Remodelers · Lynn Haven Kitchen & Bathroom Remodelers · Lyons Kitchen & Bathroom Remodelers · Rancho Palos Verdes Kitchen & Bathroom Remodelers · Shawnee Kitchen & Bathroom Remodelers · Terrell Kitchen & Bathroom Remodelersjakethewonderdog

orourkeOriginal Author

lazypup

jakethewonderdog

orourkeOriginal Author

orourkeOriginal Author

hendricus

jakethewonderdog

orourkeOriginal Author

jakethewonderdog

orourkeOriginal Author

lazypup

orourkeOriginal Author

orourkeOriginal Author

jake2007

orourkeOriginal Author

lazypup

orourkeOriginal Author

orourkeOriginal Author