JB Weld on ABS drainpipe

pjb999

15 years ago

Related Stories

SHOWERSYour Guide to Shower Floor Materials

Discover the pros and cons of marble, travertine, porcelain and more

Full StorySO apparently JB is pretty good for this- previous homeowners had drilled 3 holes into a drainpipe putting up a shelf and never knew it, I noticed a little dampness on the floor and around the cleanout at the base of the pipe. I consider myself so, so lucky as this pipe serviced a toilet as well as a shower/bath/sink yet nothing overly stinky came out, I did end up removing a 7' section of drywall around it ( the end of an alcove, basically) because the capilliary effect propelled water along the wall between the plastic moisture barrier and the drywall. One section near was soft the rest of the drywall was more or less fine and might have been ok if it was allowed to dry, but I didn't want the possibility of mould so I removed more than I had to.

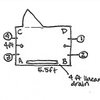

The area does not allow a lot of room to work and I decided cutting the whole section out and replacing it (the pipe) might be worse by the time I cut it all out and turned the pipe joiners into slip rings (no room for the pipe to move) I might be better off patching those 3 little holes not to mention the potential mess cutting out a sewer pipe....

So in the end I patched the holes with JB weld, made sure the holes were dry (just used plain JB couldn't find the water stuff) and filled allowing a key in the hole, then a second layer using used dryer sheet like fibreglass cloth, then a final layer over it,

It has sat for several weeks (got waylaid after I pulled the wall out) and the repairs seem perfect - not a sign of a leak. I also ran JB arould a pipe joint as double insurance after a tight fit with the abs cement etc, and all that looks good too.

Just in case anyone's wondering - JB seems to do ok for this.

brickeyee

pjb999Original Author

Related Professionals

Wolf Trap Handyman · Channahon Handyman · Chantilly Handyman · North New Hyde Park Handyman · Normal Kitchen & Bathroom Remodelers · Citrus Park Kitchen & Bathroom Remodelers · Fort Myers Kitchen & Bathroom Remodelers · Galena Park Kitchen & Bathroom Remodelers · Glen Allen Kitchen & Bathroom Remodelers · Glendale Kitchen & Bathroom Remodelers · Independence Kitchen & Bathroom Remodelers · Lomita Kitchen & Bathroom Remodelers · South Barrington Kitchen & Bathroom Remodelers · Tuckahoe Kitchen & Bathroom Remodelers · Gibsonton Kitchen & Bathroom Remodelerslazypup

pjb999Original Author

brickeyee

lazypup

pjb999Original Author

pjb999Original Author