supporting copper pipe

consed

18 years ago

Featured Answer

Sort by:Oldest

Comments (7)

Related Stories

METALCopper, the Dynamic Topper

Time changes copper’s appearance on walls, fireplaces and more, but your love of its look may spring eternal

Full Story

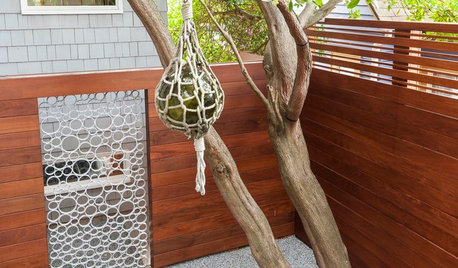

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

ARCHITECTURECylinders — More Than Architects’ Pipe Dreams

They may look fanciful, but cylinders can serve practical purposes in architectural designs

Full Story

DECORATING GUIDESDecorating for Children: How Your House Can Support Creative Play

When you encourage kids to use their imagination, you help them learn problem solving, relationship building and creativity

Full Story

SHOP HOUZZShop Houzz: A Pop of Copper

Get an autumn-perfect coppery glow in the bath, living room and kitchen

Full Story0

KITCHEN DESIGNKitchen Sinks: Antibacterial Copper Gives Kitchens a Gleam

If you want a classic sink material that rejects bacteria, babies your dishes and develops a patina, copper is for you

Full Story

COTTAGE STYLEHouzz Tour: Beach Shack Reborn as a Copper-Clad Cottage

A tranquil home with a copper exterior lets in ocean air, sunlight and greenery on a challenging site

Full Story

REMODELING GUIDES15 Ways to Design With Copper

Get Inspired to Add the Long-Lasting Beauty of Copper to Your Home

Full Story

HOUZZ TOURSMy Houzz: Copper Tones Warm an Amsterdam Apartment

Paint, editing and a crush on copper help an Amsterdam resident conquer his compact space

Full Story

lazypup