black iron gas feed for stove

mclemens

12 years ago

Related Stories

KITCHEN DESIGNKitchen of the Week: Updated French Country Style Centered on a Stove

What to do when you've got a beautiful Lacanche range? Make it the star of your kitchen renovation, for starters

Full Story

VINTAGE STYLERevel in Retro With Vintage and New Kitchen Appliances

Give your kitchen old-fashioned charm with refrigerators and stoves that recall yesteryear — even if they were made just yesterday

Full Story

KITCHEN DESIGNWhat to Know When Choosing a Range Hood

Find out the types of kitchen range hoods available and the options for customized units

Full Story

LIVING ROOMSHow to Convert Your Wood-Burning Fireplace

Learn about inserts and other options for switching your fireplace from wood to gas or electric

Full Story

KITCHEN APPLIANCESFind the Right Cooktop for Your Kitchen

For a kitchen setup with sizzle, deciding between gas and electric is only the first hurdle. This guide can help

Full Story

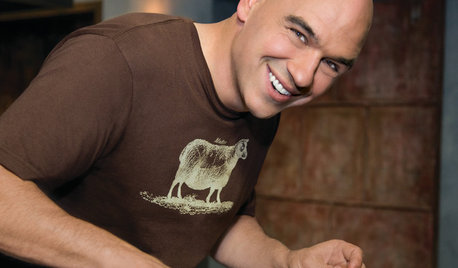

TASTEMAKERSPro Chefs Dish on Kitchens: Michael Symon Shares His Tastes

What does an Iron Chef go for in kitchen layout, appliances and lighting? Find out here

Full Story

DECORATING GUIDES25 Design Trends Coming to Homes Near You in 2016

From black stainless steel appliances to outdoor fabrics used indoors, these design ideas will be gaining steam in the new year

Full Story

KITCHEN DESIGN5 Favorite Granites for Gorgeous Kitchen Countertops

See granite types from white to black in action, and learn which cabinet finishes and fixture materials pair best with each

Full Story

KITCHEN DESIGN9 Popular Stovetop Options — Plus Tips for Choosing the Right One

Pick a stovetop that fits your lifestyle and your kitchen style with this mini guide that covers all the basics

Full Story

MOST POPULAR15 Remodeling ‘Uh-Oh’ Moments to Learn From

The road to successful design is paved with disaster stories. What’s yours?

Full Story

Dayspring Construction - Kitchen and Baths

lazypup

Related Professionals

Hillcrest Heights Handyman · North New Hyde Park Handyman · Beach Park Kitchen & Bathroom Remodelers · 20781 Kitchen & Bathroom Remodelers · 93927 Kitchen & Bathroom Remodelers · Honolulu Kitchen & Bathroom Remodelers · Jefferson Hills Kitchen & Bathroom Remodelers · Linton Hall Kitchen & Bathroom Remodelers · Rochester Kitchen & Bathroom Remodelers · Roselle Kitchen & Bathroom Remodelers · Southampton Kitchen & Bathroom Remodelers · Terrell Kitchen & Bathroom Remodelers · Tulsa Kitchen & Bathroom Remodelers · West Palm Beach Kitchen & Bathroom Remodelers · Ojus Kitchen & Bath Fixturesbrickeyee

mclemensOriginal Author

lazypup

brickeyee

mclemensOriginal Author

mclemensOriginal Author

User

lazypup

mclemensOriginal Author