PEX and Connector Fittings

GreenDog194

12 years ago

Related Stories

BATHROOM DESIGNConvert Your Tub Space to a Shower — the Fixtures-Shopping Phase

Step 2 in swapping your tub for a sleek new shower: Determine your mechanical needs and buy quality fixtures

Full Story

LIGHTINGA Beginner’s Guide to Lighting in Layers

Discover the secrets of combining light sources to create richer-looking and more flexible living spaces

Full Story

HOUZZ TOURSMy Houzz: An 1874 Cabin Completes a Rustic Oregon Home

It took 10 years and a hand-hewn log cabin to build this labor of love. See the results of one couple's patience and vision

Full Story

DIY PROJECTSNeat Little Project: Make a Mini Wooden Wall Console

Use this handy holder by a bed or desk for eyeglasses or jewelry, or as a convenient charging station

Full Story

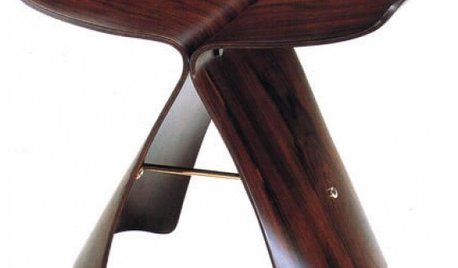

FURNITUREModern Icons: Sori Yanagi's Butterfly Stool

Rooms take flight with the organic beauty of this sculptural midcentury modern seat

Full Story

FLOORSWhat to Ask When Considering Heated Floors

These questions can help you decide if radiant floor heating is right for you — and what your options are

Full Story

FURNITUREWhat to Know Before You Buy a Sectional

Learn about sizes, arm setups, seat types and more to get the right sectional for your space

Full Story

FLOORSFloors Warm Up to Radiant Heat

Toasty toes and money saved are just two benefits of radiant heat under your concrete, wood or tile floors

Full Story

FLOORSIs Radiant Heating or Cooling Right for You?

Questions to ask before you go for one of these temperature systems in your floors or walls (yes, walls)

Full Story

GREAT HOME PROJECTSHow to Add a Radiant Heat System

Enjoy comfy, consistent temperatures and maybe even energy savings with hydronic heating and cooling

Full StoryMore Discussions

lazypup

GreenDog194Original Author

Related Professionals

Springdale Handyman · Channahon Handyman · Shamong Kitchen & Bathroom Remodelers · Athens Kitchen & Bathroom Remodelers · Clovis Kitchen & Bathroom Remodelers · Deerfield Beach Kitchen & Bathroom Remodelers · Emeryville Kitchen & Bathroom Remodelers · Glendale Kitchen & Bathroom Remodelers · Overland Park Kitchen & Bathroom Remodelers · South Lake Tahoe Kitchen & Bathroom Remodelers · Spokane Kitchen & Bathroom Remodelers · Thonotosassa Kitchen & Bathroom Remodelers · Toledo Kitchen & Bathroom Remodelers · Middlesex Kitchen & Bathroom Remodelers · South Jordan Kitchen & Bathroom Remodelerslazypup

User

GreenDog194Original Author

User

lazypup

GreenDog194Original Author

User

lazypup

brickeyee

SparklingWater

brickeyee

GreenDog194Original Author