Cast iron drain lines

apg4

10 years ago

Related Stories

KITCHEN DESIGNKitchen Sinks: Enameled Cast Iron for Attractive Durability

Strong, shiny and sustainable, an enameled cast iron sink can bring character to your kitchen

Full Story

BATHROOM DESIGNHow to Choose the Best Drain for Your Shower

Don't settle for a cheap fix when you can pick a shower drain that suits your style preferences and renovation codes alike

Full Story

KITCHEN COUNTERTOPSCast Concrete Countertops With a Personal Twist

From frame making to pouring to inlays, learn how concrete counters are cast — and how an artisan embellishes them

Full Story

REMODELING GUIDESOriginal Home Details: What to Keep, What to Cast Off

Renovate an older home without regrets with this insight on the details worth preserving

Full Story

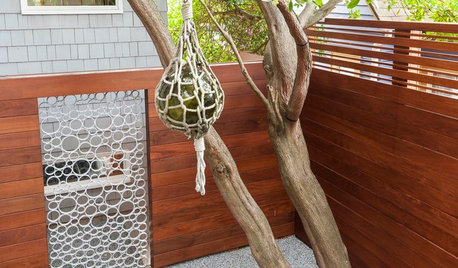

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

GARDENING AND LANDSCAPINGEco-Friendly Fire Pits: Casting Backyard Campfires in a New Light

Wood burning may be discouraged — even illegal in places — but that needn't mean forsaking the fire pit. Try one of these alternatives

Full Story

EXTERIORSWhere Front Yards Collide: Property Lines in Pictures

Some could be twins; others channel the Odd Couple. You may never look at property boundaries the same way again

Full Story

KITCHEN DESIGN8 Stylish Sink Types for Kitchens of All Kinds

Choose the wrong sink and your kitchen renovation efforts may go down the drain — these sinks will let you clean up in the style department

Full Story

BATHROOM DESIGNConvert Your Tub Space Into a Shower — Waterproofing and Drainage

Step 4 in swapping your tub for a sleek new shower: Pick your waterproofing materials and drain, and don't forget to test

Full Story

BATHROOM DESIGNMakeover Magic: Period Style for an All-New 1920s Bathroom

Leaky fixtures and water damage got the heave-ho, while the entire bathroom got a crisp new look in line with the home's style

Full Story

dgeist

DreamingoftheUP

Related Professionals

Harmony Plumbers · Springdale Handyman · Plainview Kitchen & Bathroom Remodelers · Boca Raton Kitchen & Bathroom Remodelers · Clovis Kitchen & Bathroom Remodelers · Cocoa Beach Kitchen & Bathroom Remodelers · Kendale Lakes Kitchen & Bathroom Remodelers · Lakeside Kitchen & Bathroom Remodelers · Pinellas Park Kitchen & Bathroom Remodelers · Sioux Falls Kitchen & Bathroom Remodelers · Vashon Kitchen & Bathroom Remodelers · Lawndale Kitchen & Bathroom Remodelers · Shaker Heights Kitchen & Bathroom Remodelers · Westminster Kitchen & Bathroom Remodelers · Palestine Kitchen & Bathroom Remodelersklem1

apg4Original Author

jackfre

DreamingoftheUP

DreamingoftheUP

jackfre

apg4Original Author

bus_driver

klem1

apg4Original Author