Teflon Tape vs. Pipe Thread Compound...

gblentz

17 years ago

Featured Answer

Comments (37)

lazypup

17 years agolast modified: 9 years agoRelated Professionals

Harmony Plumbers · Vienna Handyman · East Tulare County Kitchen & Bathroom Remodelers · Albuquerque Kitchen & Bathroom Remodelers · Avondale Kitchen & Bathroom Remodelers · Brentwood Kitchen & Bathroom Remodelers · Fort Washington Kitchen & Bathroom Remodelers · Franconia Kitchen & Bathroom Remodelers · Honolulu Kitchen & Bathroom Remodelers · Kettering Kitchen & Bathroom Remodelers · Newberg Kitchen & Bathroom Remodelers · Overland Park Kitchen & Bathroom Remodelers · Park Ridge Kitchen & Bathroom Remodelers · Saint Helens Kitchen & Bathroom Remodelers · Winchester Kitchen & Bathroom Remodelersjakethewonderdog

17 years agolast modified: 9 years agolazypup

17 years agolast modified: 9 years agomr_havac

17 years agolast modified: 9 years agogblentz

17 years agolast modified: 9 years agopjb999

17 years agolast modified: 9 years agolazypup

17 years agolast modified: 9 years agojca1

17 years agolast modified: 9 years agopjb999

17 years agolast modified: 9 years agoKevin Garabedian

17 years agolast modified: 9 years agomrplumber101

16 years agolast modified: 9 years agobrickeyee

16 years agolast modified: 9 years agomarknmt

16 years agolast modified: 9 years agojason1083

16 years agolast modified: 9 years agomarknmt

16 years agolast modified: 9 years agorockoc

16 years agolast modified: 9 years agolazypup

16 years agolast modified: 9 years agojca1

16 years agolast modified: 9 years agomatt_r

16 years agolast modified: 9 years agojason1083

16 years agolast modified: 9 years agomatt_r

16 years agolast modified: 9 years agorbjohansen

16 years agolast modified: 9 years agosaxmaan1

16 years agolast modified: 9 years agotintin55

16 years agolast modified: 9 years agodan33

15 years agolast modified: 9 years agobrickeyee

15 years agolast modified: 9 years agodan33

15 years agolast modified: 9 years agomspitza

14 years agolast modified: 9 years agolazypup

14 years agolast modified: 9 years agofranklinz

13 years agolast modified: 9 years agogpbruc_comcast_net

13 years agolast modified: 9 years agoTAB29_aol_com

12 years agolast modified: 9 years agoalphonse

12 years agolast modified: 9 years agoTAB29_aol_com

12 years agolast modified: 9 years agoGaryJay

12 years agolast modified: 9 years agoalphonse

12 years agolast modified: 9 years ago

Related Stories

WORKING WITH PROSHow to Work With a Plumber

Follow these guidelines, and your plumbing job will flow as smoothly as water through clean pipes

Full Story

GREAT HOME PROJECTSHow to Switch to a Tankless Water Heater

New project for a new year: Swap your conventional heater for an energy-saving model — and don’t be fooled by misinformation

Full Story

BATHROOM DESIGNConvert Your Tub Space to a Shower — the Fixtures-Shopping Phase

Step 2 in swapping your tub for a sleek new shower: Determine your mechanical needs and buy quality fixtures

Full Story

KITCHEN DESIGNShow Us Your Fabulous DIY Kitchen

Did you do a great job when you did it yourself? We want to see and hear about it

Full Story

DECORATING GUIDESBulletproof Decorating: Upholstery That Stands Up to Anything

Kids and pets are no match for fabrics as durable as these, which meet higher style standards than ever

Full Story

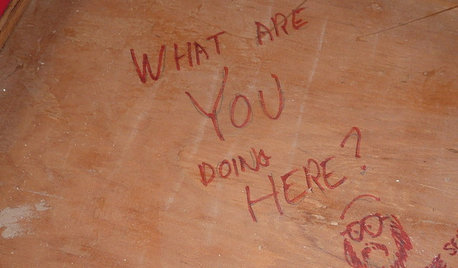

FUN HOUZZDoes Your Home Have a Hidden Message?

If you have ever left or found a message during a construction project, we want to see it!

Full StorySponsored

Central Ohio's Trusted Home Remodeler Specializing in Kitchens & Baths

More Discussions

castoff